FA-1300 Series

FA-1300 Unit Mounted Model (250W)

New line-up of 250W models. For improved working efficiency with high heat storage components.

| Package Contents |

|---|

FA-1300 Series Features

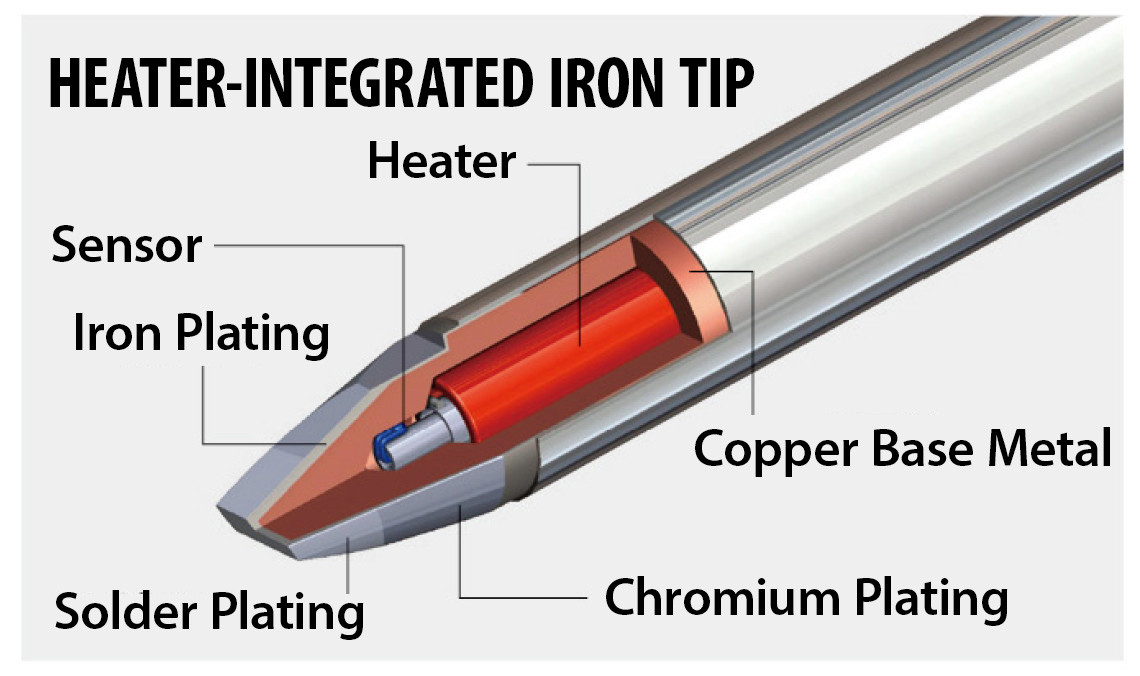

- Heater-integrated iron tip gives both accurate tip temperatures and lower running costs.

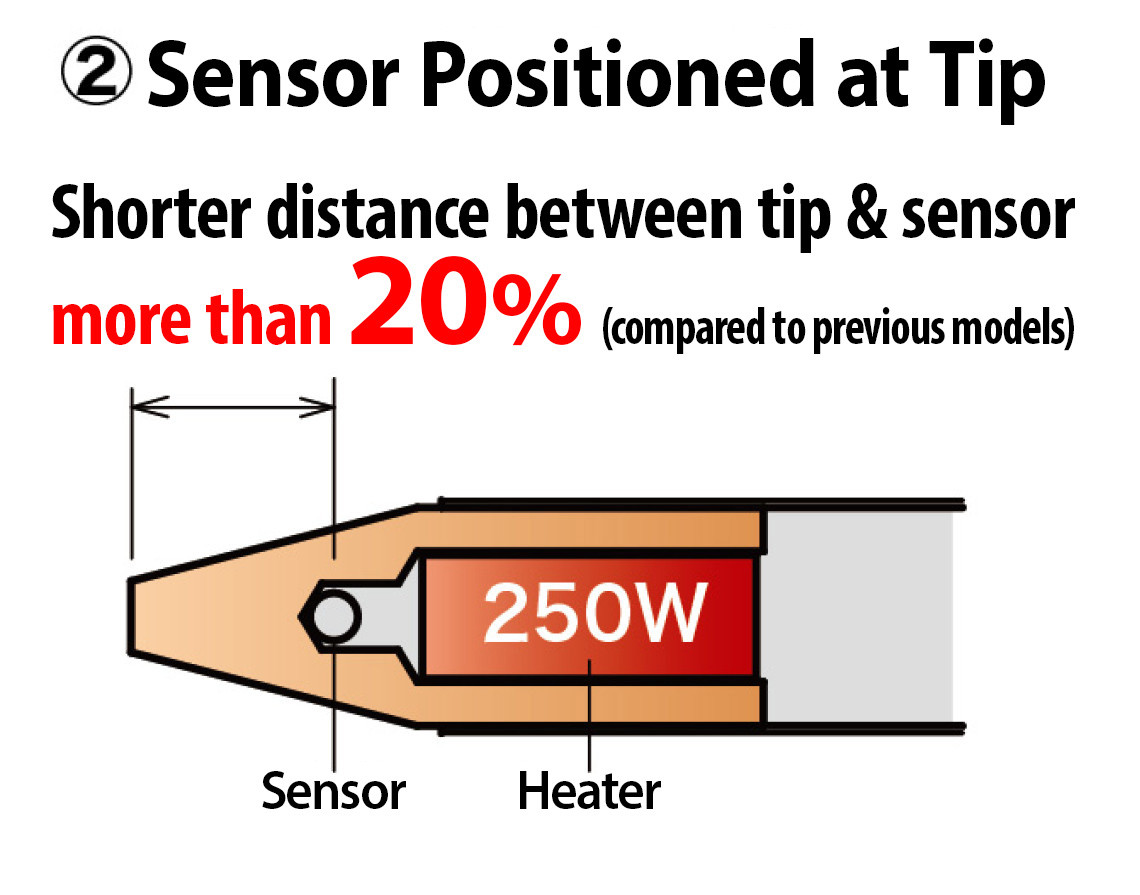

Compact sensor eliminates effects of direct heat from the heater. - Rise time and heat recovery time are greatly reduced thanks to the heater’s tight coil, and the sensor near the tip end.

- In-house production of iron tips. Flexible manufacturing to meet your needs.

- N2 soldering is available.

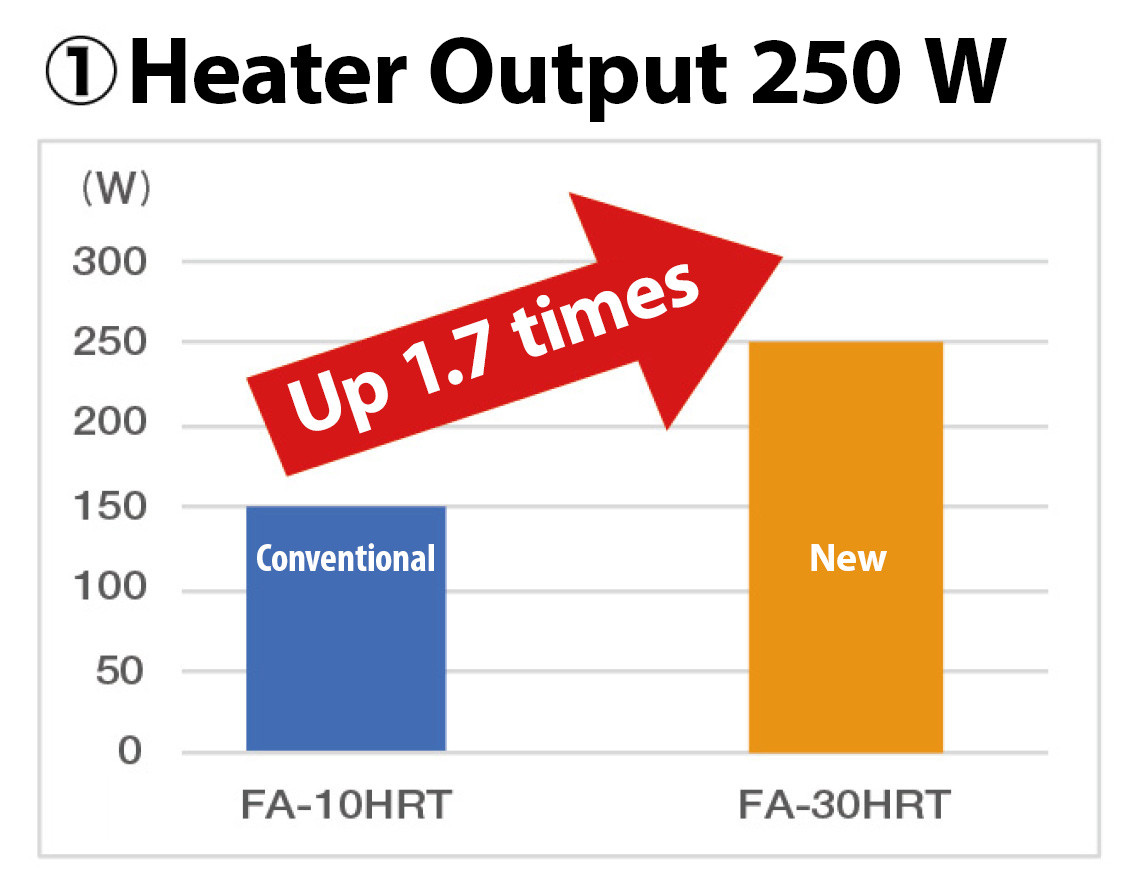

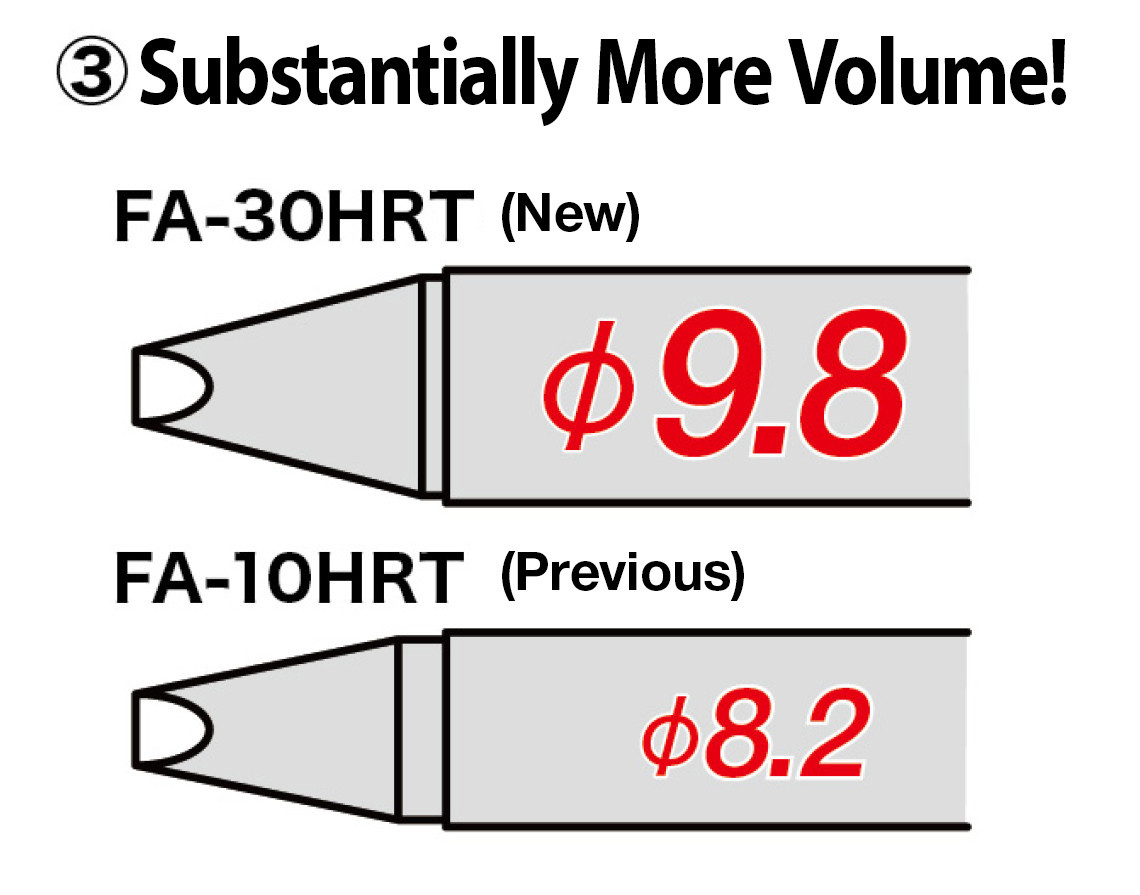

250W High-powered Heater FA-30HRT Tip Series

Improved working efficiency with high heat storage components such as automotive parts!

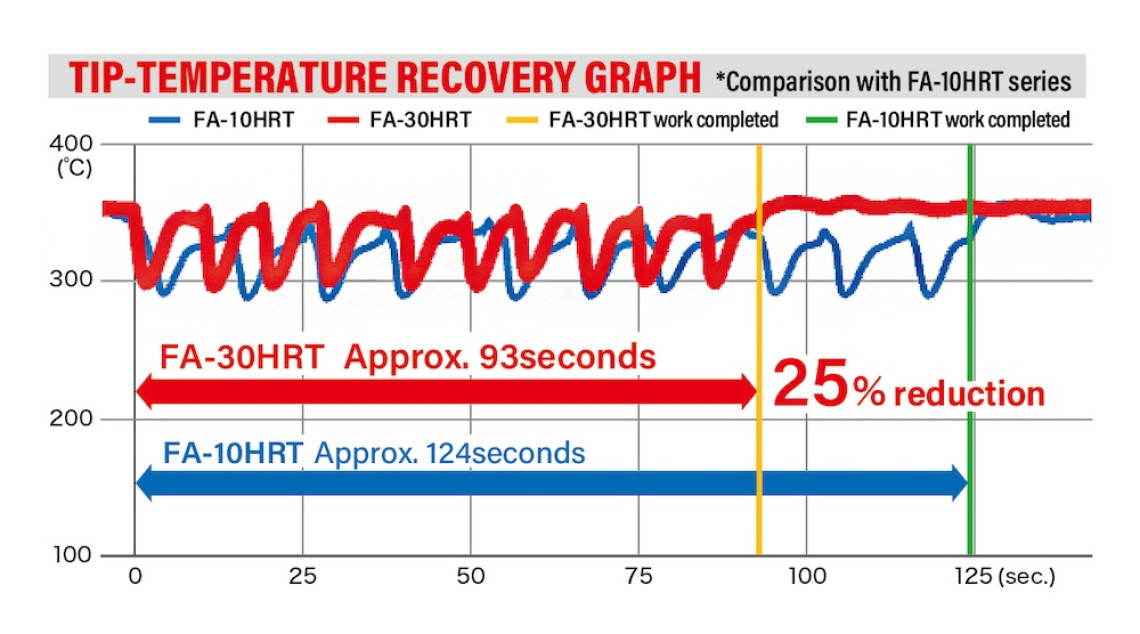

Three new elements realize heating performance *25% higher than conventional.

*Comparison with FA-10HRT series

Evolved Soldering System

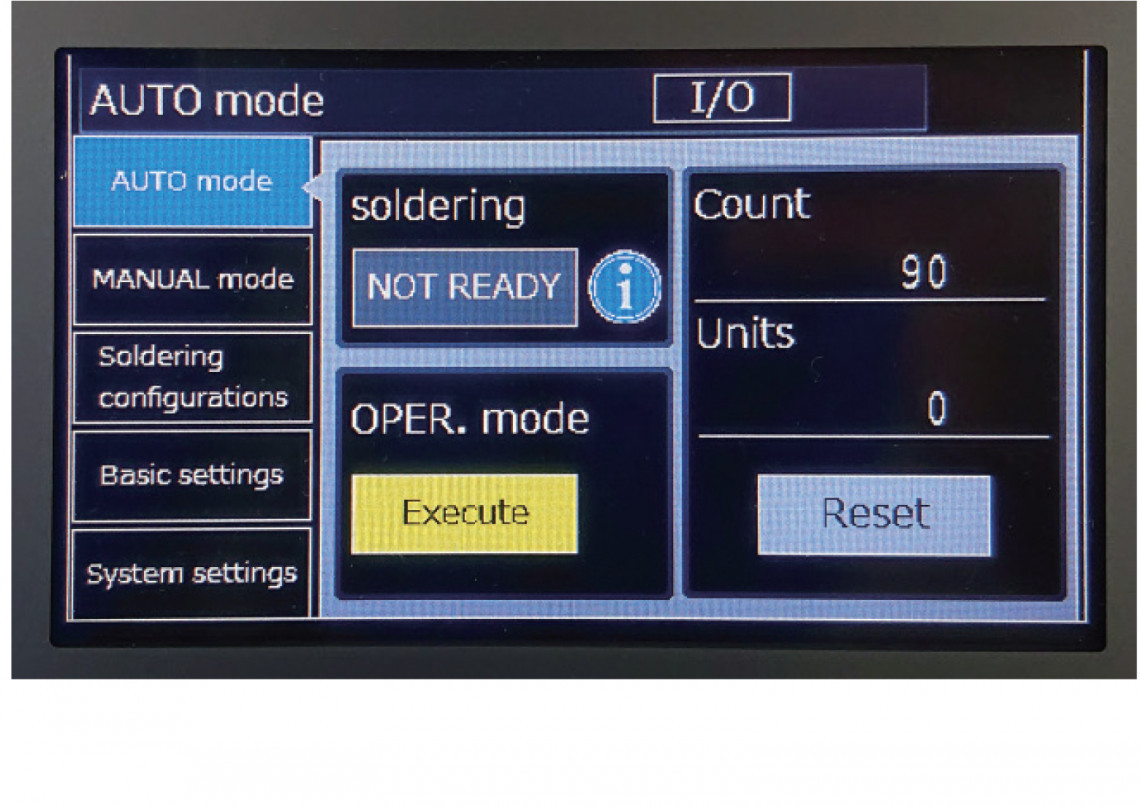

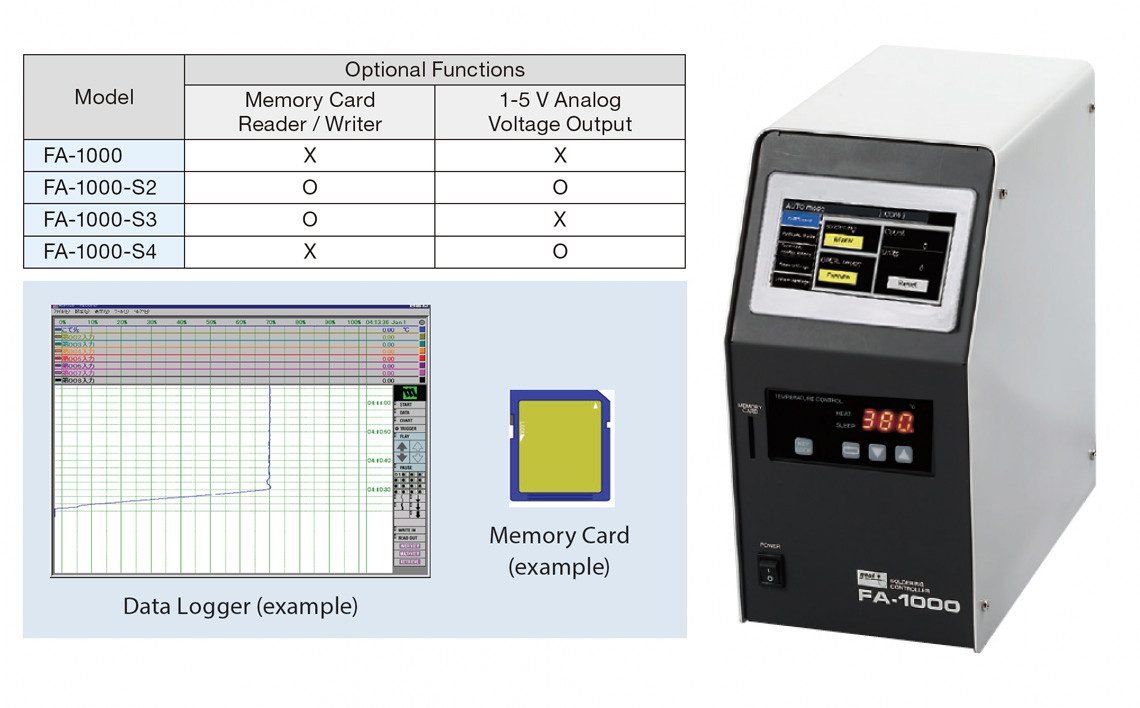

■ Control Unit FA-1000

High-performance control unit capable of controlling each unit

- 256 soldering conditions can be registered.

- Easy-to-operate large color touch-panel.

- Available in Japanese, English, Chinese, and Spanish.

- Standard I/O port can be connected with various robots.

- Memory card function, and tip temperature output to monitor can be added as options.

- Memory Card Reader / Writer

You can save soldering configurations on memory cards. Very useful to copy the data to other FA-1000 Control Units and also to backup.

- Tip Temperature Monitor Output

Tip temperature is output by 1-5 V analog voltage. An off-the-shelf data logger would be helpful to monitor temperature control.

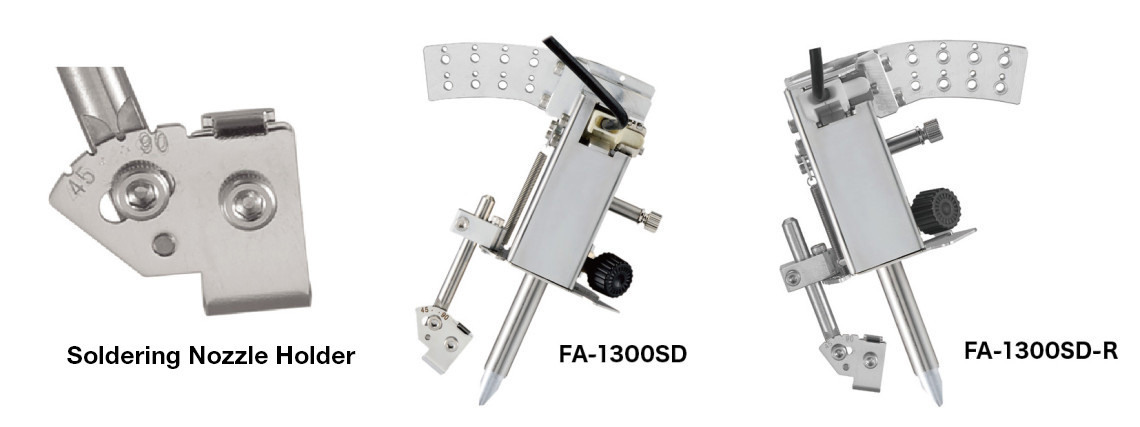

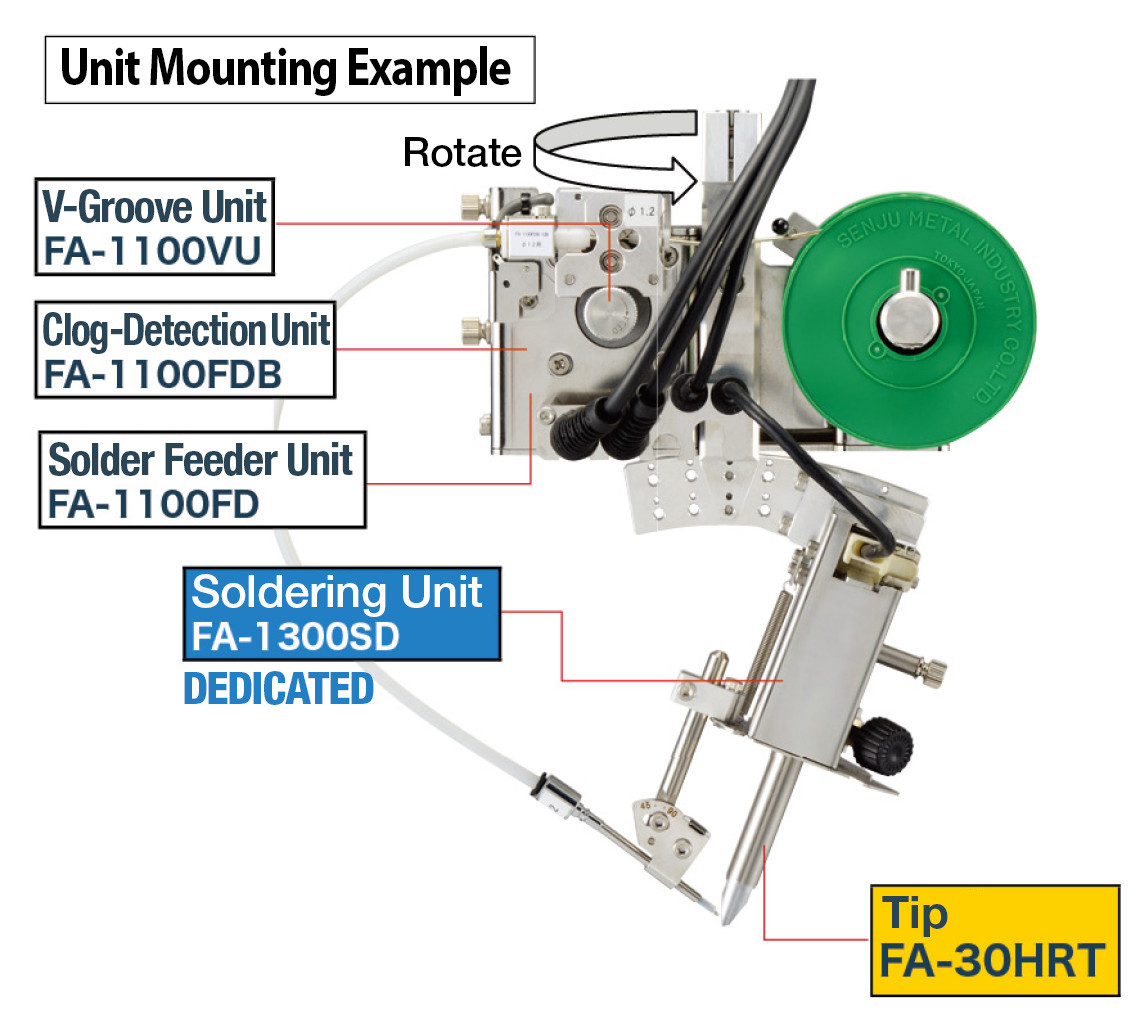

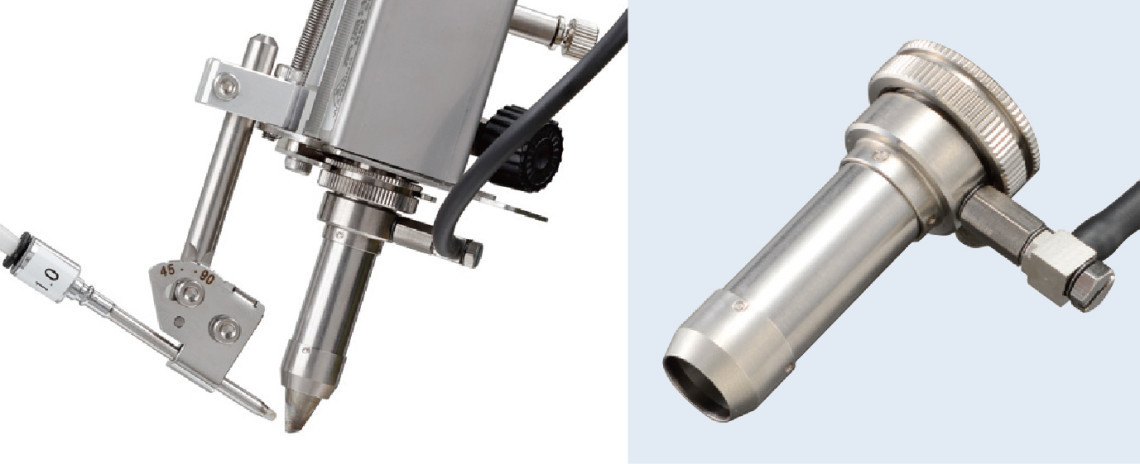

■ Soldering Unit FA-1300SD/FA-1300SD-R

(Dedicated to FA-30HRT)

- Compact and easily installed on robots and devices.

- Weight is 370g or less. Can be attached to weak robots with carriable power 500g.

- Can check the angle of Solder Nozzle with a scale on the Soldering Nozzle Holder (45-90°).

- Solder-feeding angle can be changed to ±30°.

- Easier to replace tips with new improved mechanism. (PAT.)

- Angle-Setting Plate may be attached the other way, upon request. Please choose attachment when you order.

Can be set to deliver the solder under the soldering iron tip.

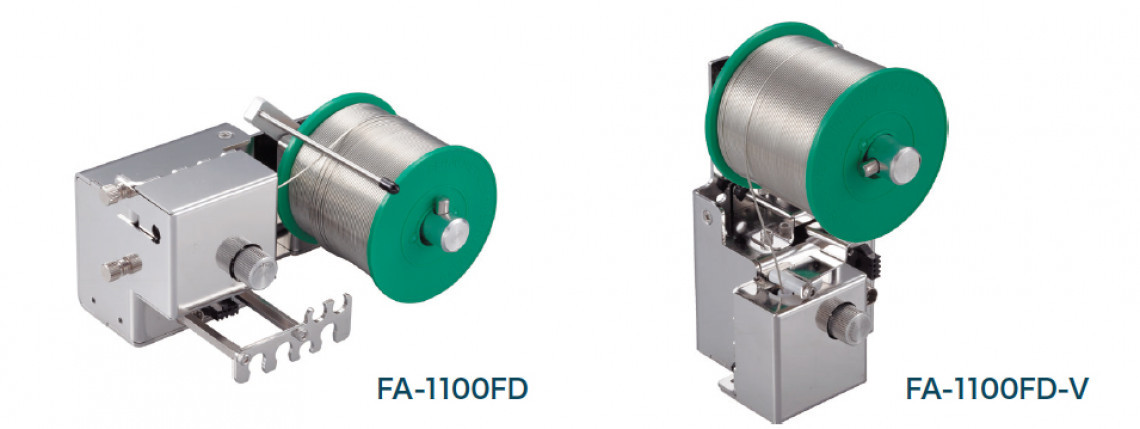

■ Solder Feeder Unit FA-1100FD/FA-1100FD-V

- Compact, integrated Reel Holder/Feeder Unit.

- Stepping motor controls feed amount precisely.

- Solder-Clog/No-Solder sensors built-in.

- One action to replace solder.

- Original sensor for vertical/horizontal attachment.

- Good for automation with third party robot.

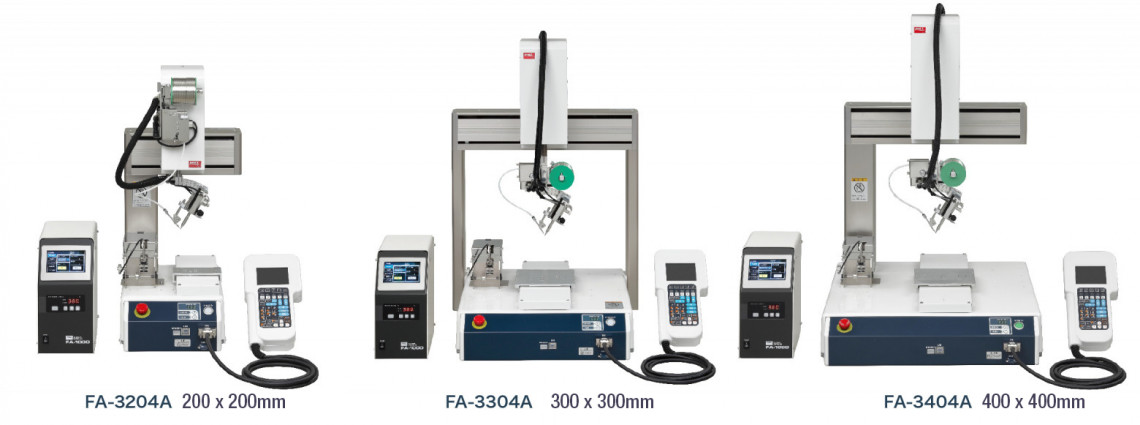

| Robot | FA-3204A | FA-3304A / FA-3404A |

| Model | FA-1100FD-V | FA-1100FD |

■ Robot Mounting Block FA-1100J4B-S/FA-1100J4B-L

- Block to connect the robot and Soldering Unit (FA-1100SD/FA-1100SD-R).

- Can connect to the robot of shaft-dia. 10mm.

- Solder Feeder Unit (FD-1100FD) can be attached to FA-1100J4B-L.

| Robot | FA-3204A | FA-3304A / FA-3404A |

| Model | FA-1100J4B-S | FA-1100J4B-L |

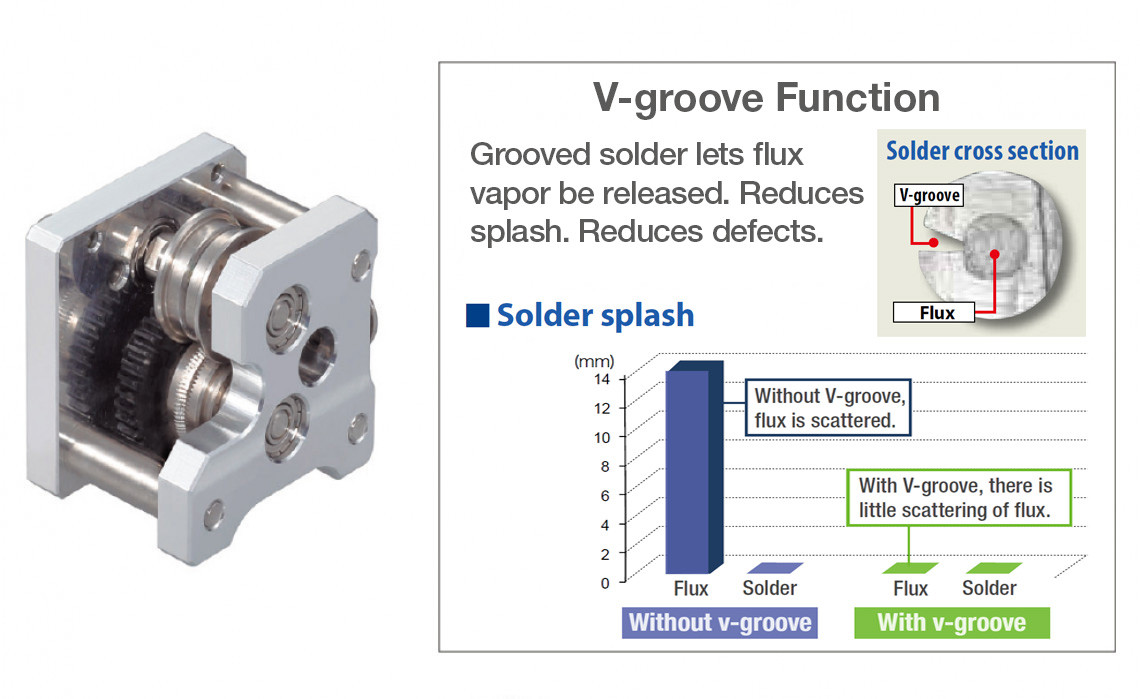

■ V-Groove Unit FA-1100VU

- Swappable gearbox can make V-groove.

- Vertical grooved rollers prevent solder slippage.

- V-groove processing on the solder lets flux gas escape, greatly reducing solder and flux scattering which causes defects.

| Model | Solder Dia. |

| FA-1100VU-05 | Φ0.5 |

| FA-1100VU-06 | Φ0.6(Φ0.65) |

| FA-1100VU-08 | Φ0.8 |

| FA-1100VU-10 | Φ1.0 |

| FA-1100VU-12 | Φ1.2 |

■ Clog-Detection Unit FA-1100FDB

- Detects solder clogs immediately. Prevents solder buckling. (When using FA-1000FD)

- Easy to attach and maintain with one-touch joint nozzle.

- Longer, straight nozzle. Solder goes straighter.

- Easy to adjust the distance between tip and nozzle.

| Robot | FA-3204A | FA-3304A / FA-3404A | Solder Dia. |

| Model | FA-1100FDB-05A | FA-1100FDB-05B | Φ0.5 |

| FA-1100FDB-06A | FA-1100FDB-06B | Φ0.6(Φ0.65) | |

| FA-1100FDB-08A | FA-1100FDB-08B | Φ0.8 | |

| FA-1100FDB-10A | FA-1100FDB-10B | Φ1.0 | |

| FA-1100FDB-12A | FA-1100FDB-12B | Φ1.2 | |

| Tube Length | 450mm | 300mm |

■ Air Blow Tip Cleaner FA-1100CL

- Removes excess solder on tip.

- Bigger size (160% of previous model), and internal air-blow shield greatly reduce solder splash.

- Easy to clean and maintain. Attach/detach the dust catcher in one action.

- Angle scale on the Blow Nozzle for numerical control.

■ Diagonal Driver FA-1100SL

- The up-down strokes of Soldering Unit (FA-1100SD / FA-1100SD-R) are air-driven.

- Tip slides in neatly, avoiding components.

- Up/Down detection sensor. Stroke length: 8mm

Teaching Pendant

FA-JR3000-TP2

Teaching pendant for intuitive coordinate setting. Interactive format makes teaching easier.

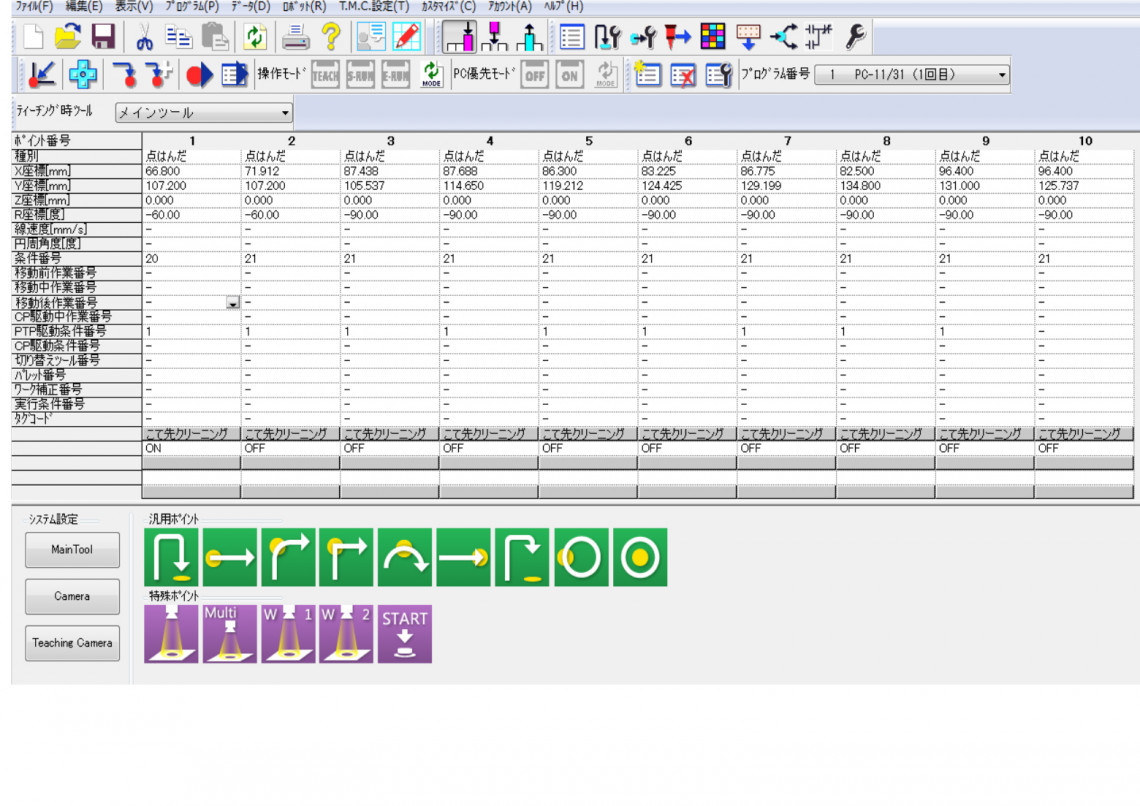

PC Software

FA-JR3000-PC2

Software for applications to create, edit, and save teaching or customized data on a PC.

A limited version software is included as standard, which can only send/receive and save data.

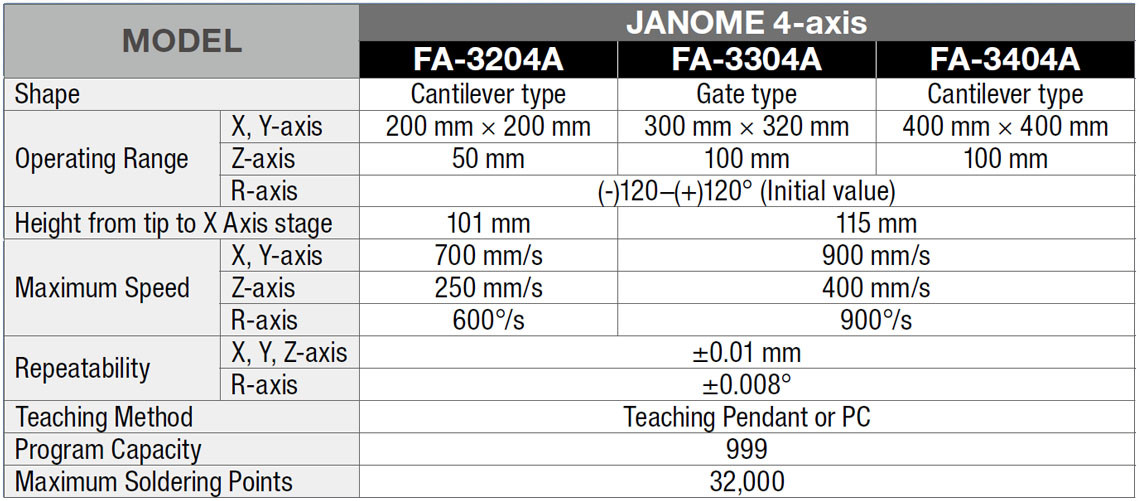

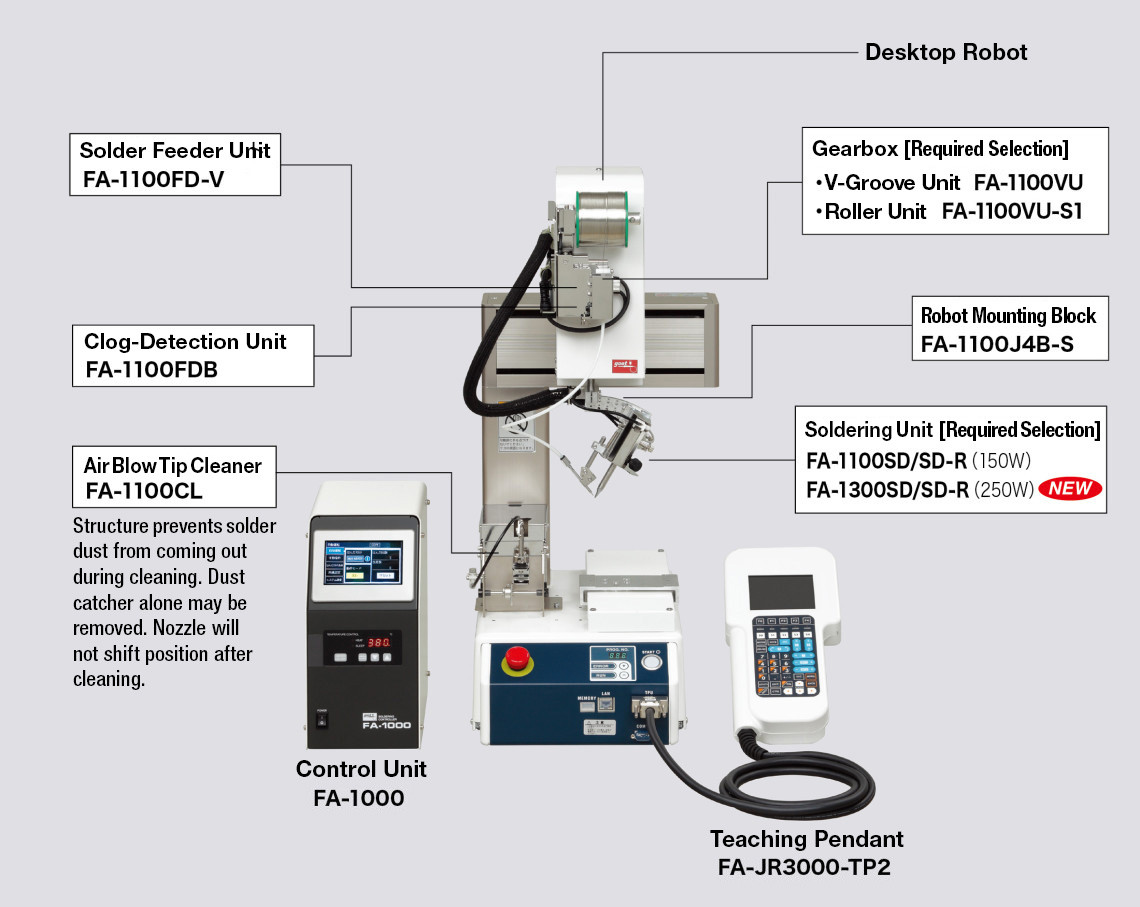

Sample Desktop Robot Configuration

・Easy teaching by dedicated soldering program.

・Easy-to-operate Teaching Pendant

・999 programs can be registered.

・Data can be output via LAN or MEMORY port. (Optional PC software is required.)

200mm Square Setting Example

Example of a customized setup

300mm/400mm/500mm Square Setting Example

Example of a customized setup

Various Customizations Can Be Made to Fit Your Work.

Optionals

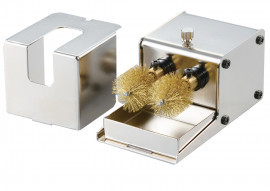

■ Brush Tip Cleaner FA-1000BC

Removes flux scorching on the tip that cannot be removed by Air-blow cleaner.

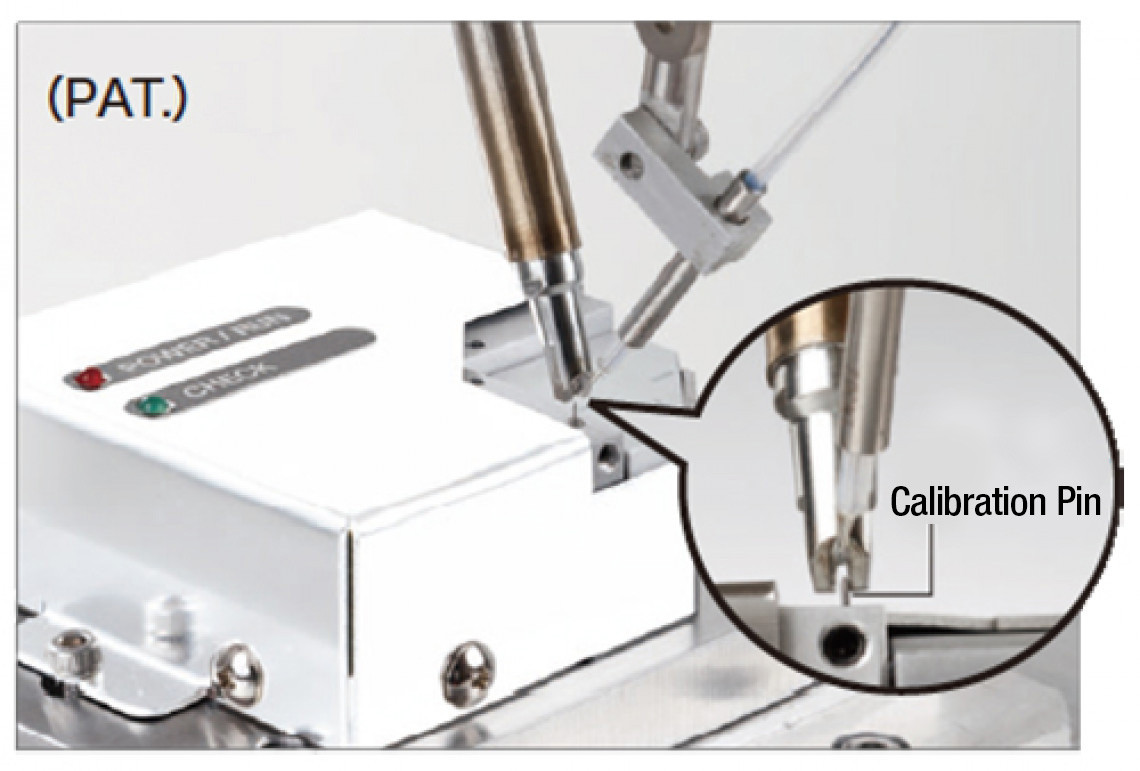

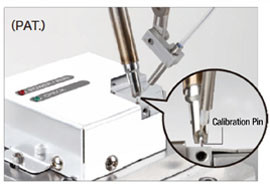

■ Mechanical Tip Correcting Unit FA-1000TCM

- Calibration pin detects and corrects position of grooved tip.

Our unique detection pin system (PAT.) can detect and correct not only conventional corrections, but also the coordinates of the inside of a grooved tip. Ideal for position correction when the groove of the tip is covered by the terminal. - Simple, compact unit

Insert new tip, set up the unit, and run the program. Tip corrects automatically.

■ N2 Nozzle FA-1300PH

- Reduced oxidation of soldered part and soldering tip.

- Improved spreading of solder wettability and cutting of solder.

N2 soldering is available by just attaching the applicable tip.

*N2 generator is required. Sold separately.

■ N2 Station NC-100R

A compact N2 station combining N2 generator and controller.

N2 gas (nitrogen gas) contained in compressed air from compressors and other sources is separated and supplied through a special separation membrane.

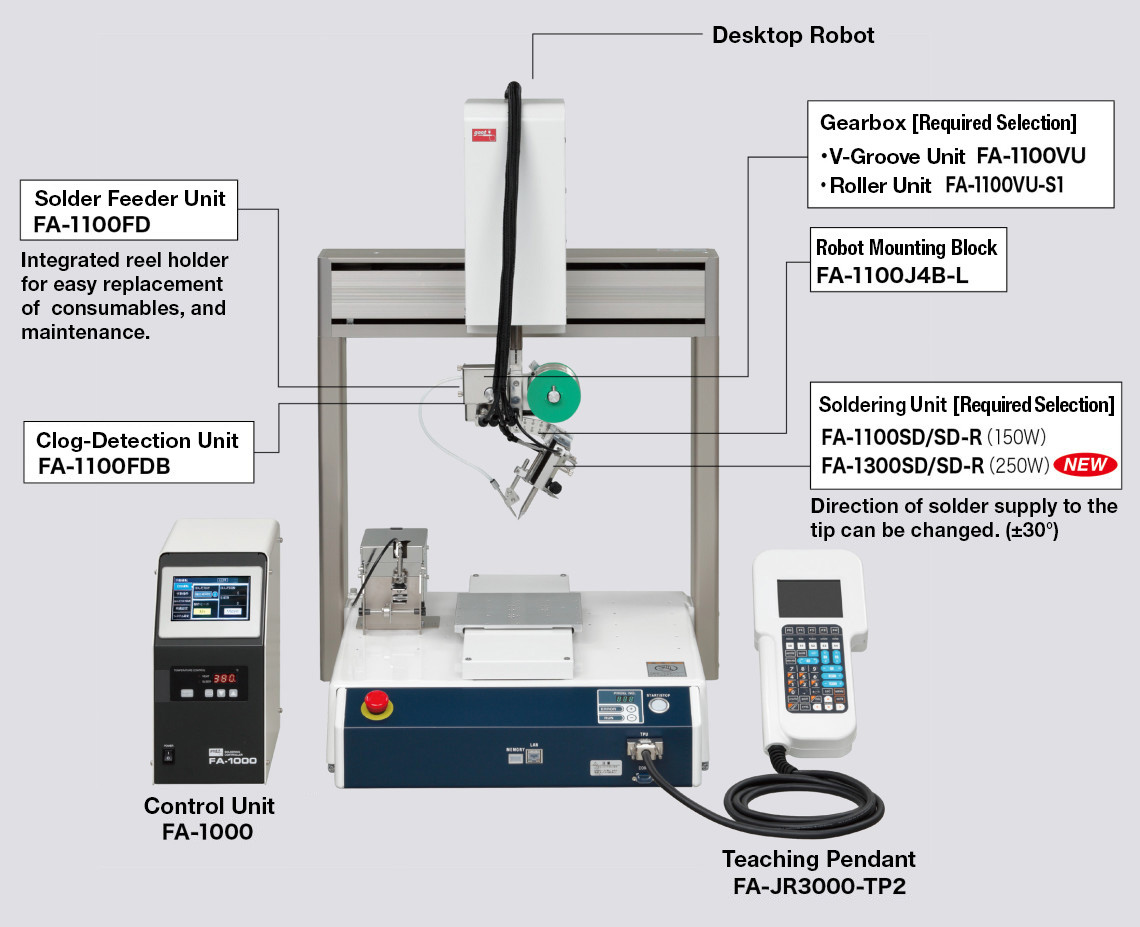

Product Specifications

| FA-3204A | FA-3304A | FA-3404A | ||

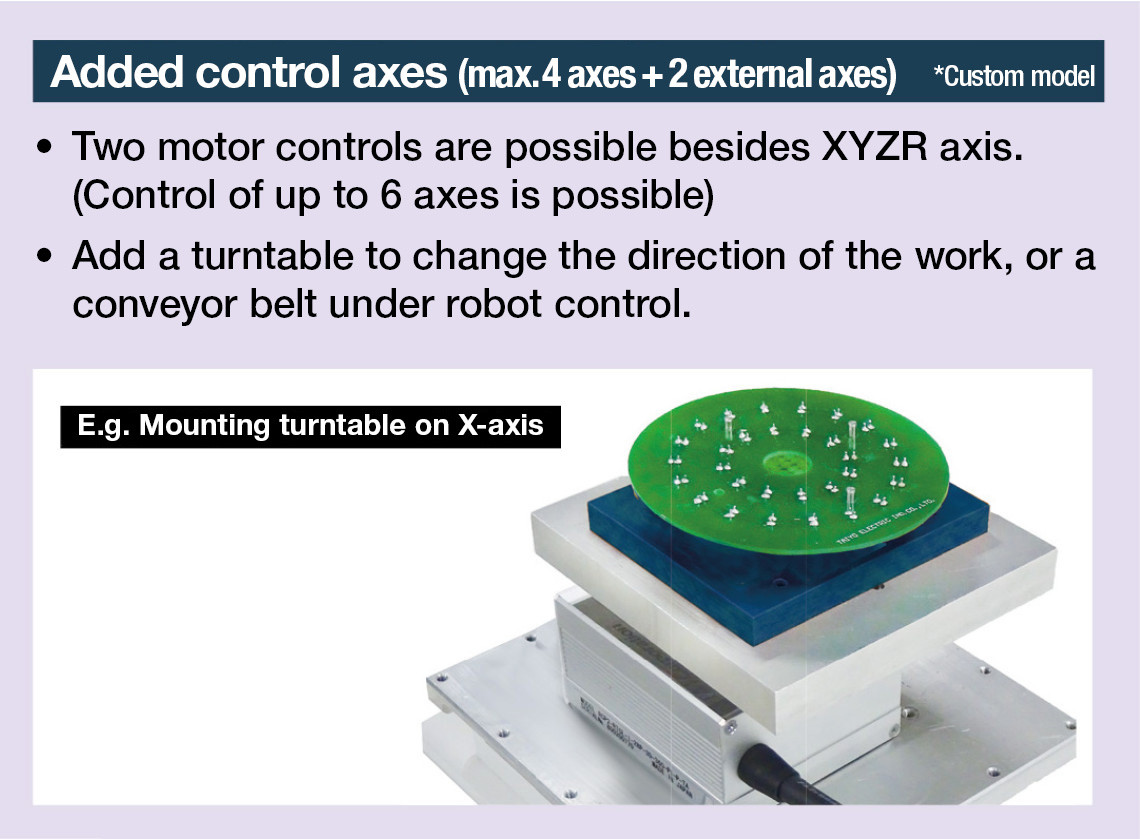

| Axis Type | Regular 4-Axis, Optional 2-Axis (Max. 6-Axis) | |||

| Operating Range | X-Axis | 200㎜ | 300㎜ | 400㎜ |

| Y-Axis | 200㎜ | 320㎜ | 400㎜ | |

| Z-Axis | 50㎜ | 100㎜ | 100㎜ | |

| R-Axis | ±120°(Max.±360°) | ±120°(Max.±360°) | ±120°(Max.±360°) | |

| Shape | Cantilever type | Gate type | Cantilever type | |

| Maximum Portable Load (Workpiece) | 7㎏ | 15㎏ | 15㎏ | |

| Maximum Speed | X, Y-Axis | 700㎜/sec | 900㎜/sec | 900㎜/sec |

| Z-Axis | 250㎜/sec | 400㎜/sec | 400㎜/sec | |

| R-Axis | 600°/sec | 900°/sec | 900°/sec | |

| Maximum Speed | X, Y, Z Combined Speed |

600㎜/sec | 850㎜/sec | 850㎜/sec |

| Repeatability | X, Y-Axis | ±0.01㎜ | ||

| Z-Axis | ±0.01㎜ | |||

| R-Axis | ±0.008° | |||

| Work Size (Maximum Size of Jig) | 200㎜×145㎜ | 300㎜×275㎜ | 400㎜×355㎜ | |

| Teaching Method | Remote teaching (JOG)/ Manual Data Input (MDI) | |||

| Teaching System | Direct teaching using the optional Teaching Pendant | |||

| Off-line teaching with optional PC Software from a PC | ||||

| Teaching Pendant Display |

Measurement Units | mm、inch | ||

| Languages | Japanese, English, French, Spanish, Italian, German, Korean, Simplified Chinese, Traditional Chinese, Czech, Vietnamese. | |||

| Program Capacity | 999 programs | |||

| Data Capacity | Up to 32,000 Points | |||

| External Input/Output |

I/O-SYS (Standard) | 16 Inputs, 16 Outputs | ||

| I/O-1 (Standard) | 8 Inputs, 8 Outputs (including 4 relay outputs) *For connecting with optional FA-1000TCM |

|||

| I/O-MT/I/O-S | I/O-MT: External Motor Control (Option) | |||

| I/O-S: For connecting with interlock device such as area sensor (Option) |

||||

| COM1 (Standard) | RC-232C for external device control, COM commands | |||

| COM2 (Standard) | RC-232C for external device control (for connecting with FA-1000) | |||

| COM3 (Standard) | RC-232C for external device control | |||

| MEMORY (Standard) | For USB memory connection | |||

| LAN (Standard) | For PC connection via the Ethernet (10BASE-T/100BASE-TX) | |||

| (Robot control via control commands, Connection to (optional) PC software) | ||||

| Simple PLC Function | Max. 100 programs, Up to 1,000 steps/1 program | |||

| Drive Method | 5 phase pulse motor drive | |||

| Control Method | PTP (Point to Point) control, CP (Continuous Path) control | |||

| Interpolation | 3-dimensional linear and arc interpolation | |||

| Power Source | AC100~120V (Single Phase) | |||

| AC220~240V (Single Phase) | ||||

| Power Consumption | 200W | |||

| Operating Enviroment |

Temperature | 0~40℃ | ||

| Relative Humidity | 20-90% (Without condensation) | |||

| Elevation | Up to 1,000m | |||

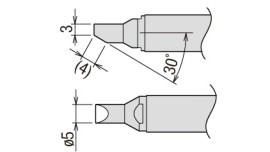

Overall View of a Tip

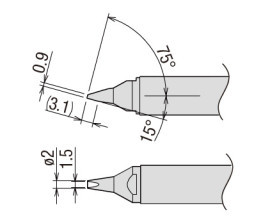

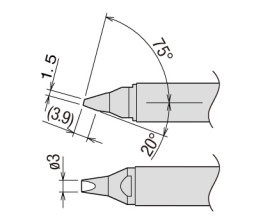

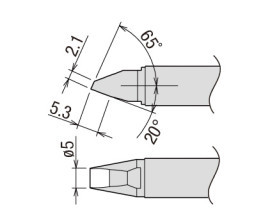

FA-30HRT Series

Replacement Tips

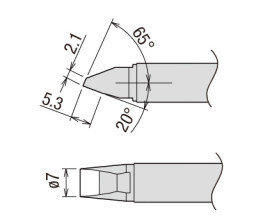

FA-30HRT-2DC

FA-30HRT-3DC

FA-30HRT-5DC

FA-30HRT-7DC

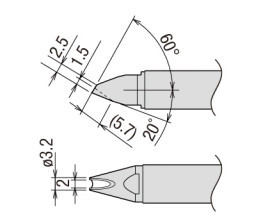

FA-30HRT-3.2DV

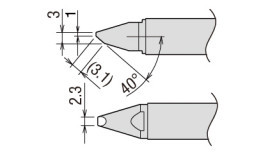

FA-30HRT-3PC

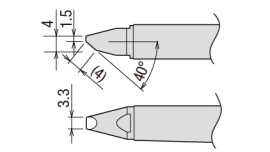

FA-30HRT-4PC

FA-30HRT-5C

-

Brush Tip Cleaner

Removes flux scorching on the tip that cannot be removed by Air-blow cleaner.

FA-1000BC

-

Mechanical Tip Correcting Unit

Insert new tip, set up the unit, and run the program. Tip corrects automatically.

FA-1000TCM

-

Solder Nozzle Tube (3 pcs)

FA-1100N

-

Brush for Brush Tip Cleaner (1 set)

FA-1000BU

-

N2 Nozzle (for FA-30HRT series)

N2 soldering is available by just attaching the applicable tip. *N2 generator is required. Sold separately.

FA-1300PH

Search Products

Search Products

Soldering Systems

Soldering Systems Soldering Irons

Soldering Irons Automatic Solder Feeders

Automatic Solder Feeders Soldering Testers/Tip Thermometers

Soldering Testers/Tip Thermometers Solder Pots

Solder Pots Surface-Mounts/SMT Products

Surface-Mounts/SMT Products Desoldering Products

Desoldering Products Soldering Accessories

Soldering Accessories Soldering Work Materials

Soldering Work Materials Heated Tools

Heated Tools Hand Tools

Hand Tools

FA-1300/1100/1000 Series

FA-1300/1100/1000 Series

Robot Units

Robot Units

Example Installations of Other Available Robots

Example Installations of Other Available Robots