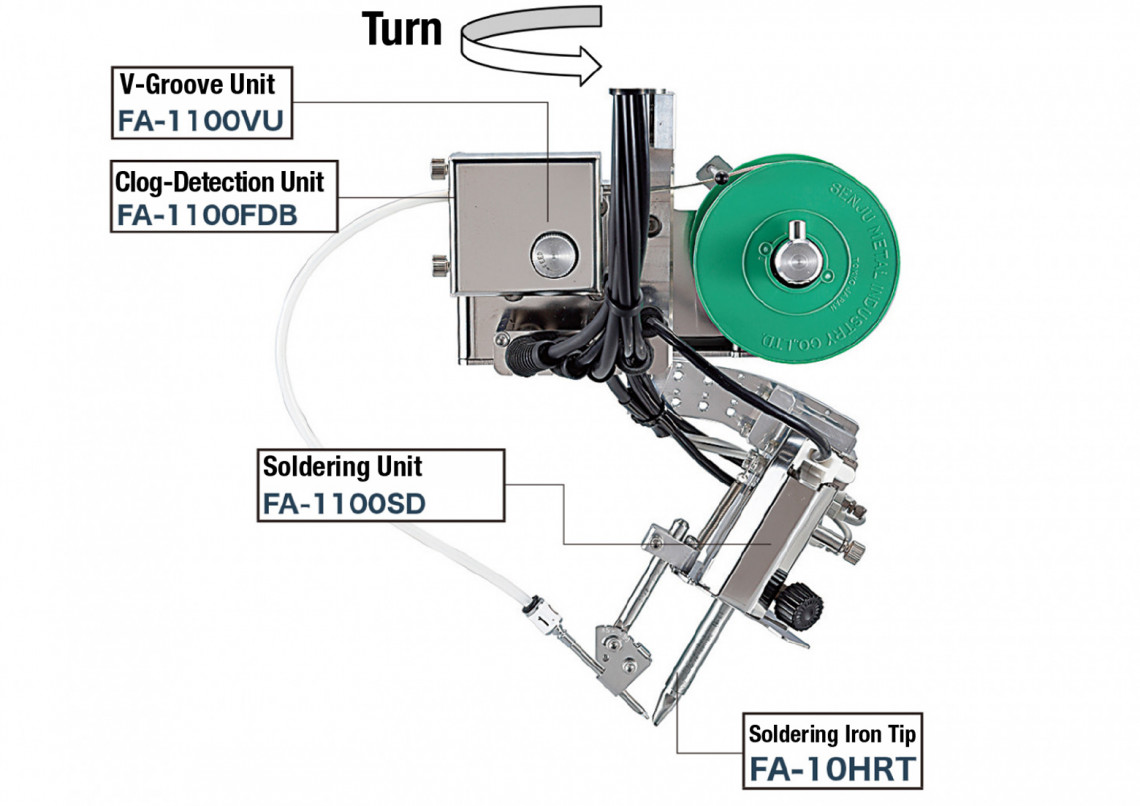

FA-1100 Unit Mounted Model

FA-1100 Series

A new model reflecting the needs of your worksite

| Package Contents |

|---|

FA-1100 Series Features

・150W heater-integrated iron tip gives both accurate tip temperatures and lower running costs. Compact sensor eliminates effects of direct heat from the heater.

・Rise time and heat recovery time are greatly reduced thanks to the heater’s tight coil, and the sensor near the tip end.

・In-house production of iron tips. Flexible manufacturing to meet your needs.

・N2 soldering is available

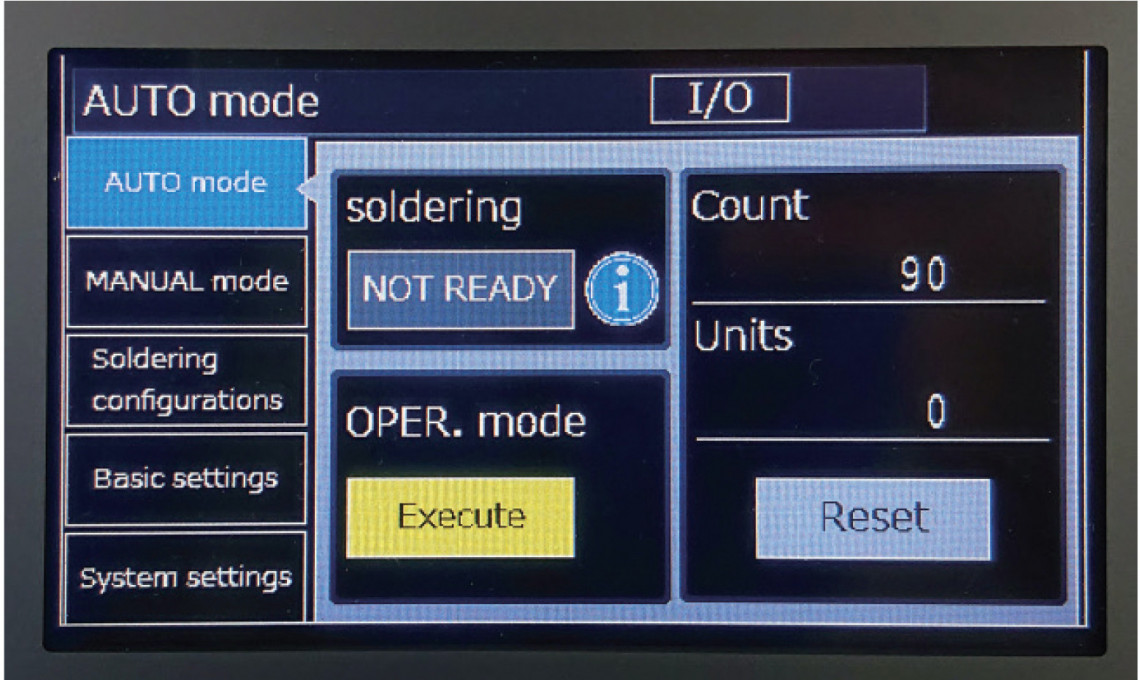

FA-1000 Controller (Common to FA-1000 and FA-1100 Series)

Large color touch-panel for improved visibility and operability.

Available in Japanese, English, Chinese, and Spanish.

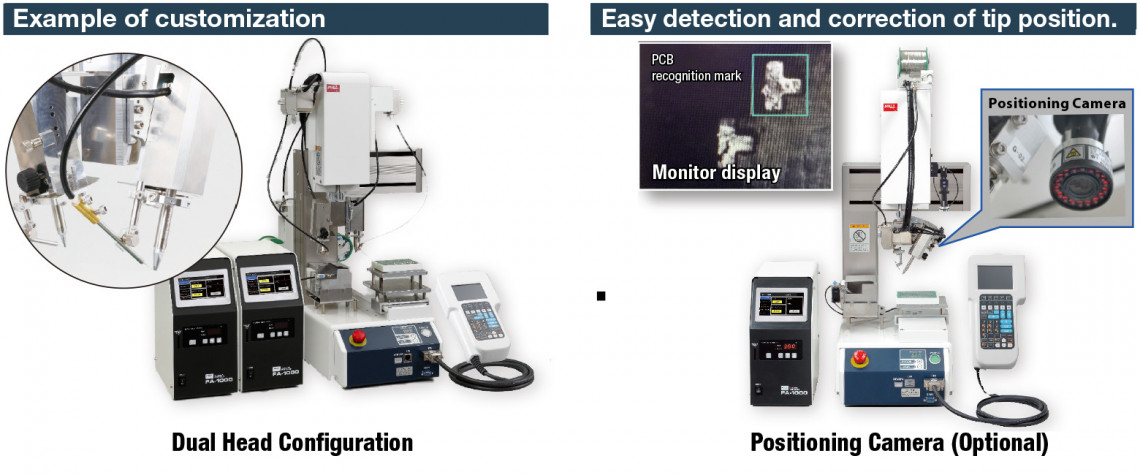

Various customizations can be made to fit your work.

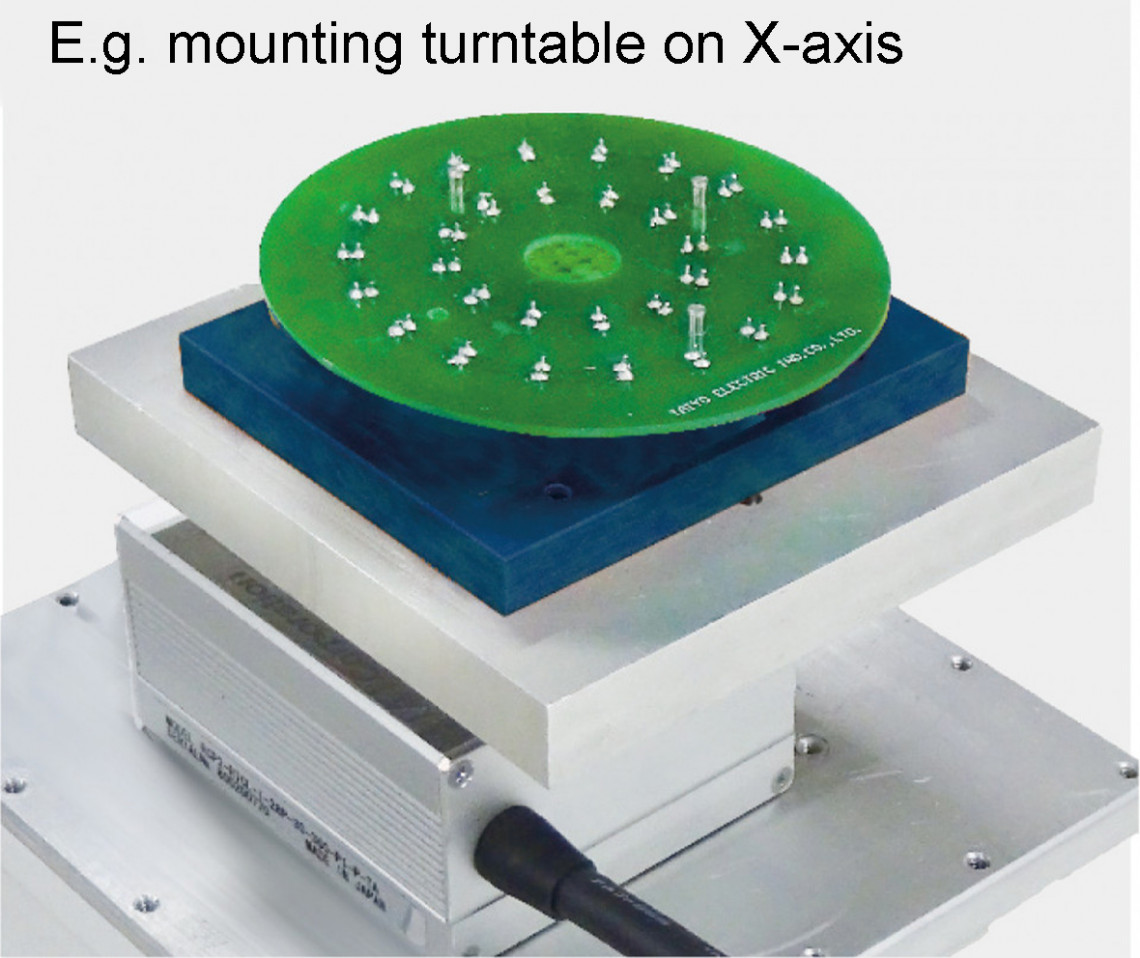

Added control axes (max. 4 axes + 2 external axes)

Two motor controls are possible besides XYZR axis. (Control of up to 6 axes is possible)

Add a turntable to change the direction of the work, or a conveyor belt under robot control.

Teaching Pendant

FA-JR3000-TP2

Teaching pendant for intuitive coordinate setting. Interactive format makes teaching easier.

PC Software

FA-JR3000-PC2

Software for applications to create, edit, and save teaching or customized data on a PC.

A limited version software is included as standard, which can only send/receive and save data.

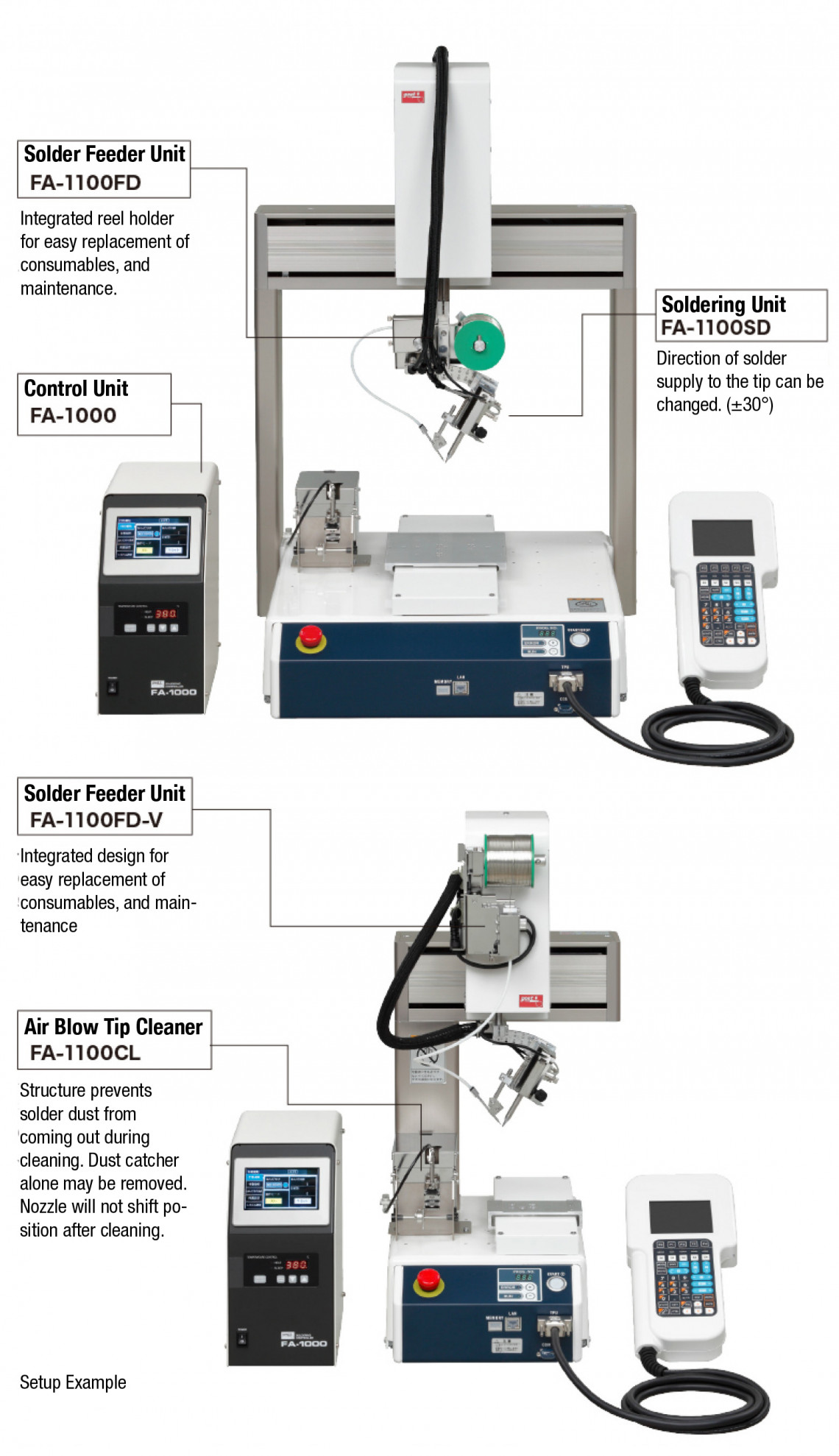

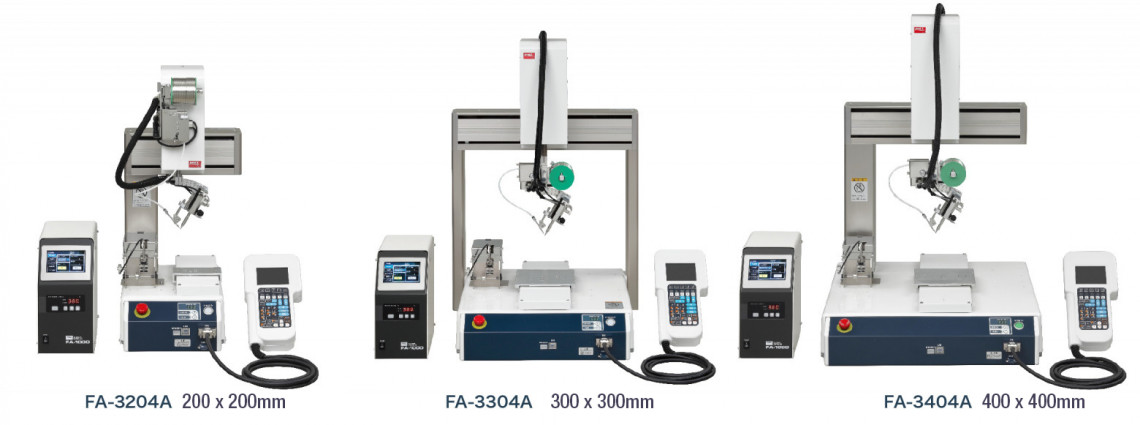

Sample Desktop Robot Configuration

・Easy teaching by dedicated soldering program.

・Easy-to-operate Teaching Pendant

・999 programs can be registered.

・Data can be output via LAN or MEMORY port. (Optional PC software is required.)

| Model | JANOME 4-Axis | |||

| FA-3204A | FA-3304A | FA-3404A | ||

|

Shape |

Cantilever type | Gate type | Cantilever type | |

|

Operating Range |

X, Y-Axis (mm) |

200 x 200 | 300 x 320 | 400 x 400 |

|

Z-Axis (mm) |

50 | 100 | 100 | |

|

R-Axis (°) |

-120 ~ +120 (default) | |||

|

Height of Tip from X-Axis Stage (mm) |

101 | 115 | ||

|

Maximum Speed |

X, Y-Axis (mm/sec) |

700 | 900 | |

|

Z-Axis (mm/sec) |

250 | 400 | ||

|

R-Axis (°/sec) |

600 | 900 | ||

|

Repeatability |

X, Y, Z-Axis (mm) |

±0.01 | ||

|

R-Axis (°) |

±0.008 | |||

|

Teaching Method |

Teaching Pendant or PC Software | |||

|

Program Capacity |

999 | |||

|

Maximum Soldering Points |

32,000 | |||

Example of Customization

200mm Square Setting Example

Product Specifications

| FA-3204A | FA-3304A | FA-3404A | ||

| Axis Type | Regular 4-Axis, Optional 2-Axis (Max. 6-Axis) | |||

| Operating Range | X-Axis | 200㎜ | 300㎜ | 400㎜ |

| Y-Axis | 200㎜ | 320㎜ | 400㎜ | |

| Z-Axis | 50㎜ | 100㎜ | 100㎜ | |

| R-Axis | ±120°(Max.±360°) | ±120°(Max.±360°) | ±120°(Max.±360°) | |

| Shape | Cantilever type | Gate type | Cantilever type | |

| Maximum Portable Load (Workpiece) | 7㎏ | 15㎏ | 15㎏ | |

| Maximum Speed | X, Y-Axis | 700㎜/sec | 900㎜/sec | 900㎜/sec |

| Z-Axis | 250㎜/sec | 400㎜/sec | 400㎜/sec | |

| R-Axis | 600°/sec | 900°/sec | 900°/sec | |

| Maximum Speed | X, Y, Z Combined Speed |

600㎜/sec | 850㎜/sec | 850㎜/sec |

| Repeatability | X, Y-Axis | ±0.01㎜ | ||

| Z-Axis | ±0.01㎜ | |||

| R-Axis | ±0.008° | |||

| Work Size (Maximum Size of Jig) | 200㎜×145㎜ | 300㎜×275㎜ | 400㎜×355㎜ | |

| Teaching Method | Remote teaching (JOG)/ Manual Data Input (MDI) | |||

| Teaching System | Direct teaching using the optional Teaching Pendant | |||

| Off-line teaching with optional PC Software from a PC | ||||

| Teaching Pendant Display |

Measurement Units | mm、inch | ||

| Languages | Japanese, English, French, Spanish, Italian, German, Korean, Simplified Chinese, Traditional Chinese, Czech, Vietnamese. | |||

| Program Capacity | 999 programs | |||

| Data Capacity | Up to 32,000 Points | |||

| External Input/Output |

I/O-SYS (Standard) | 16 Inputs, 16 Outputs | ||

| I/O-1 (Standard) | 8 Inputs, 8 Outputs (including 4 relay outputs) *For connecting with optional FA-1000TCM |

|||

| I/O-MT/I/O-S | I/O-MT: External Motor Control (Option) | |||

| I/O-S: For connecting with interlock device such as area sensor (Option) |

||||

| COM1 (Standard) | RC-232C for external device control, COM commands | |||

| COM2 (Standard) | RC-232C for external device control (for connecting with FA-1000) | |||

| COM3 (Standard) | RC-232C for external device control | |||

| MEMORY (Standard) | For USB memory connection | |||

| LAN (Standard) | For PC connection via the Ethernet (10BASE-T/100BASE-TX) | |||

| (Robot control via control commands, Connection to (optional) PC software) | ||||

| Simple PLC Function | Max. 100 programs, Up to 1,000 steps/1 program | |||

| Drive Method | 5 phase pulse motor drive | |||

| Control Method | PTP (Point to Point) control, CP (Continuous Path) control | |||

| Interpolation | 3-dimensional linear and arc interpolation | |||

| Power Source | AC100~120V (Single Phase) | |||

| AC220~240V (Single Phase) | ||||

| Power Consumption | 200W | |||

| Operating Enviroment |

Temperature | 0~40℃ | ||

| Relative Humidity | 20-90% (Without condensation) | |||

| Elevation | Up to 1,000m | |||

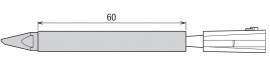

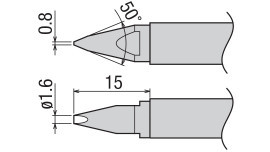

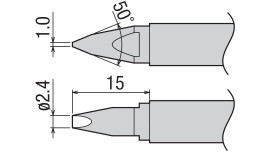

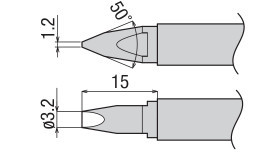

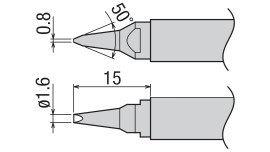

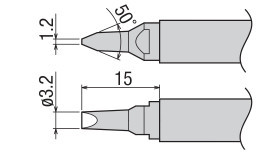

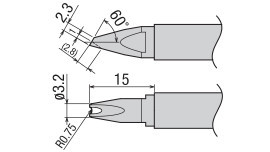

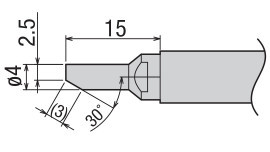

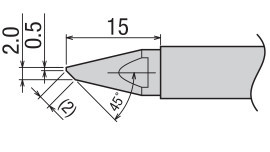

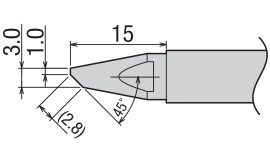

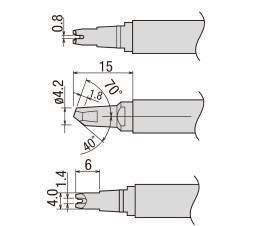

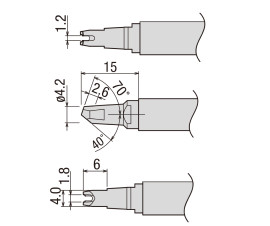

Overall View of a Tip

FA-10HRT Series

Replacement Tips

FA-10HRT-1.6D

FA-10HRT-2.4D

FA-10HRT-3.2D

FA-10HRT-1.6SD

FA-10HRT-3.2SD

FA-10HRT-3.2DV

FA-10HRT-4C

FA-10HRT-2PC

FA-10HRT-3PC

FA-10HRT-0.8W

FA-10HRT-1.2W

Search Products

Search Products

Soldering Systems

Soldering Systems Soldering Irons

Soldering Irons Automatic Solder Feeders

Automatic Solder Feeders Soldering Testers/Tip Thermometers

Soldering Testers/Tip Thermometers Solder Pots

Solder Pots Surface-Mounts/SMT Products

Surface-Mounts/SMT Products Desoldering Products

Desoldering Products Soldering Accessories

Soldering Accessories Soldering Work Materials

Soldering Work Materials Heated Tools

Heated Tools Hand Tools

Hand Tools

FA-1300/1100/1000 Series

FA-1300/1100/1000 Series

Robot Units

Robot Units

Example Installations of Other Available Robots

Example Installations of Other Available Robots