SOLDERING SYSTEM

FA-1000 Series

Economical, Soldering System

| Package Contents |

|---|

Desktop Soldering System

Common features of FA-1100 and 1000 series

• 150W integrated heater gives both accurate tip temperatures and lower running costs.

• Compact sensor eliminates direct heat from heater.

• Tight heater coil and tip sensor slash rise and recovery times.

• We make our tips in-house. Japanese quality for your needs.

• N2 soldering is available.

System can be configured by selecting the required units.

Functions required for automatic soldering are sold as separate units.

Lower price point can be realized by purchasing necessary units separately.

Please refer to FA-1000 series Configuration Guide from below.

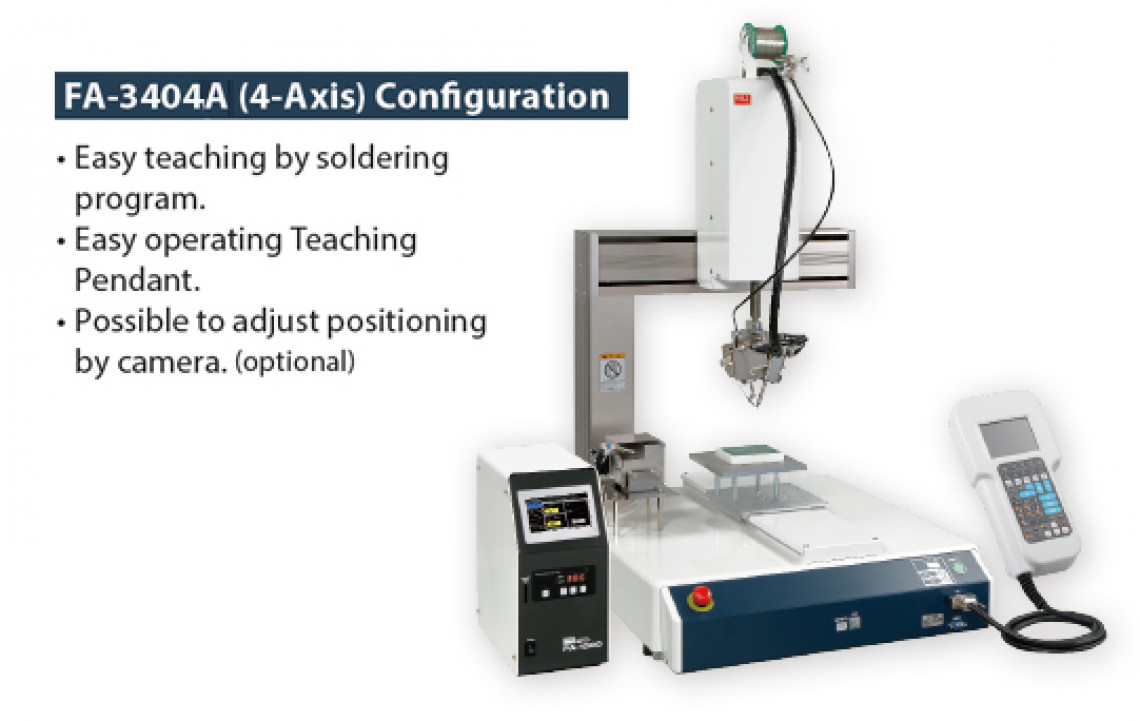

Sample Robot Configuration

Control Unit FA-1000

High performance control unit. 256 soldering conditions can be registered.

• I/O port as standard equipment can be connected with various robots.

• Easy-to-operate multi-language touch panel

• Memory card function and tip temperature output to monitor can be added as options.

About Optional Functions

• Memory Card Reader / Writer

You can save soldering configurations on memory cards. Very useful to copy the data to other FA-1000 Control Units and also to backup.

• 1-5 V Analog Voltage Output

Tip temperature is output by 1-5 V analog voltage. An off-the-shelf data logger would be helpful to monitor temperature control.

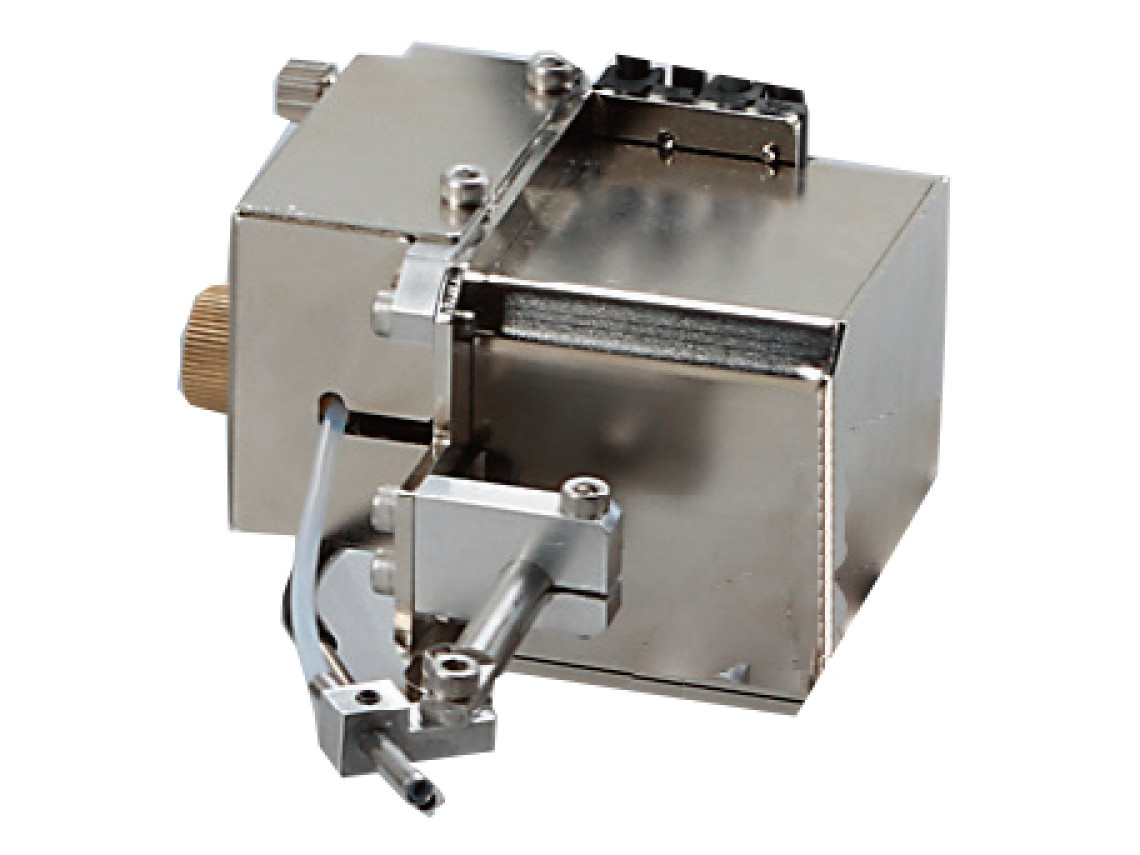

Solder Feeder Unit FA-1000FD

• Stepping motor controls feed amount precisely.

• Solder wire diameter can be changed by replacing V-groove unit / Clog-detection unit only.

• Use convenient solder-feeding knob to adjust position of solder feed.

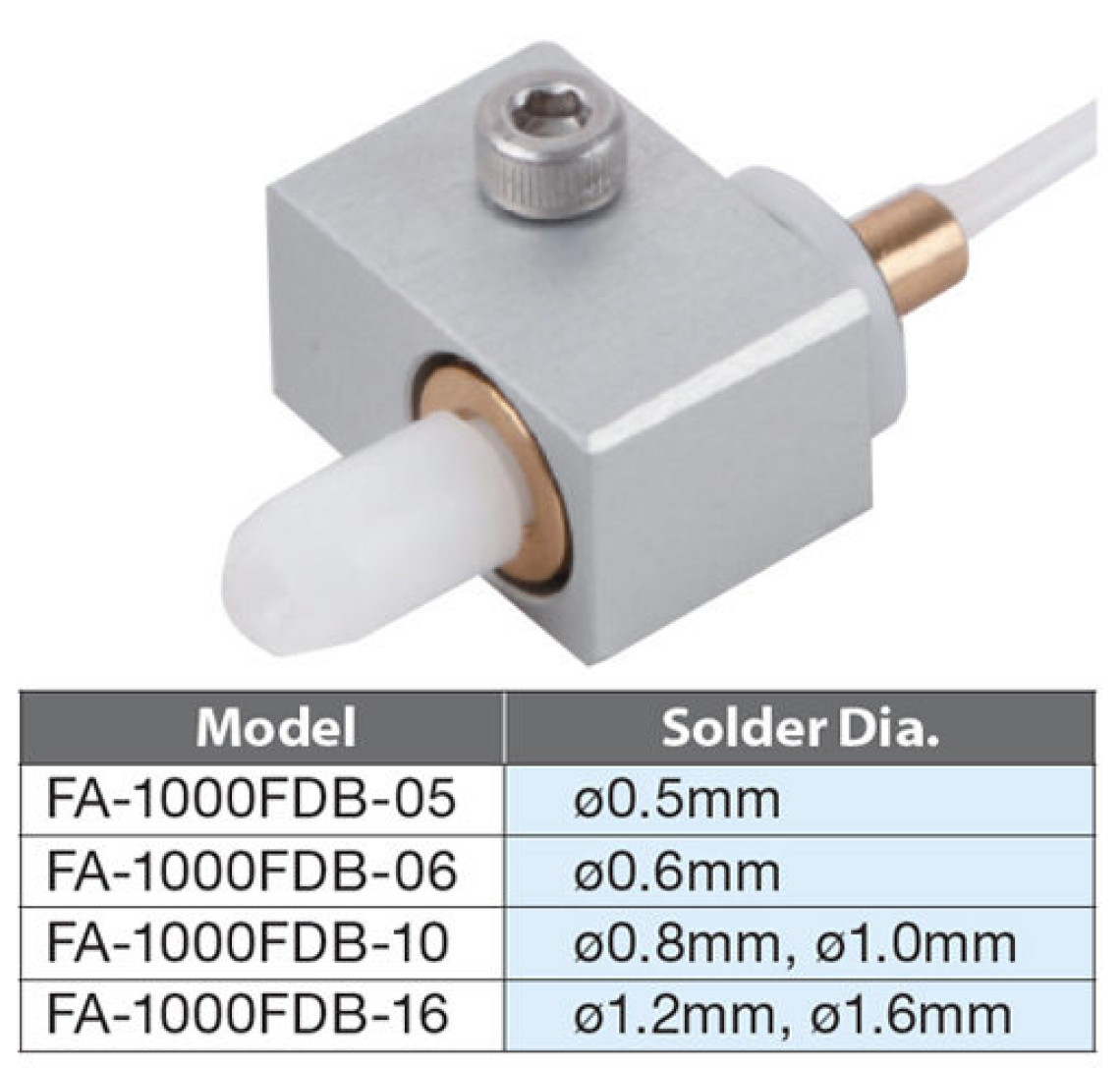

Clog-Detection Unit FA-1000FDB

Detect solder clogs immediately.

Prevent solder buckling. (When using FA-1000 FD)

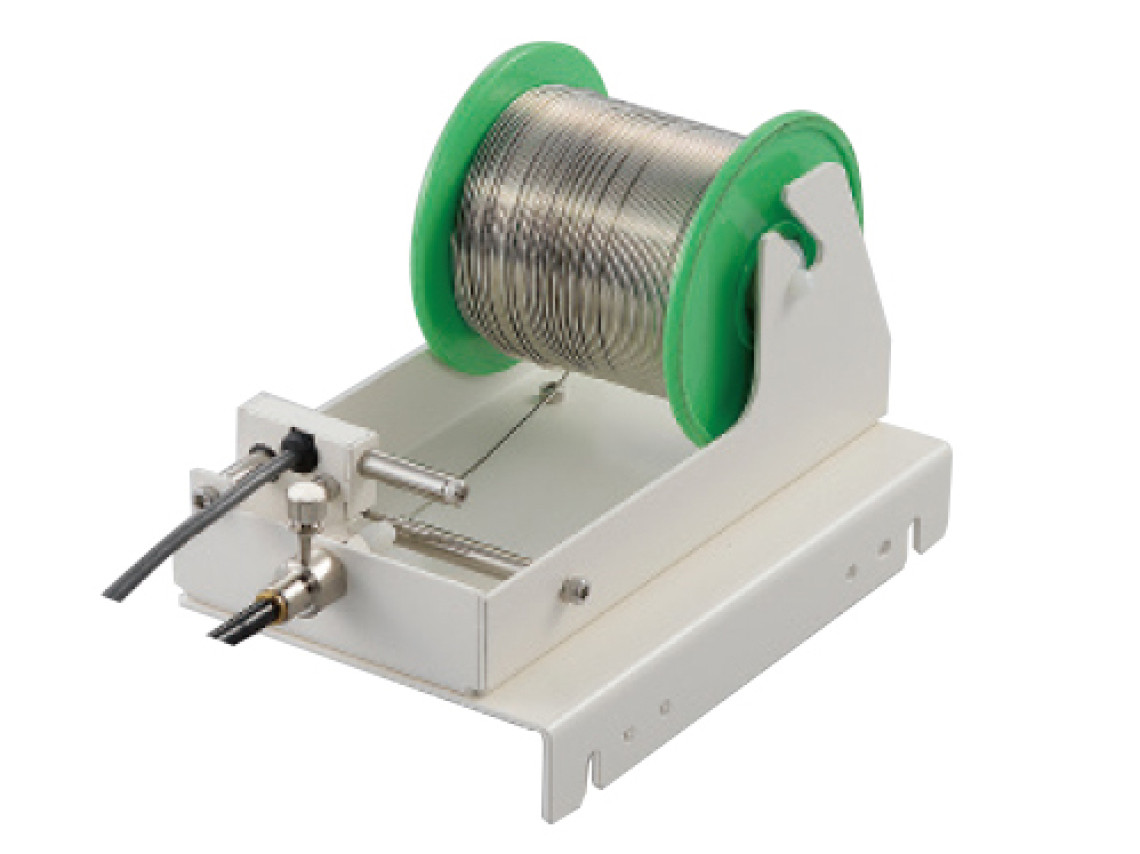

Solder Reel Holder FA-1000RH1

Solder-Finish Sensor

*Solder not included

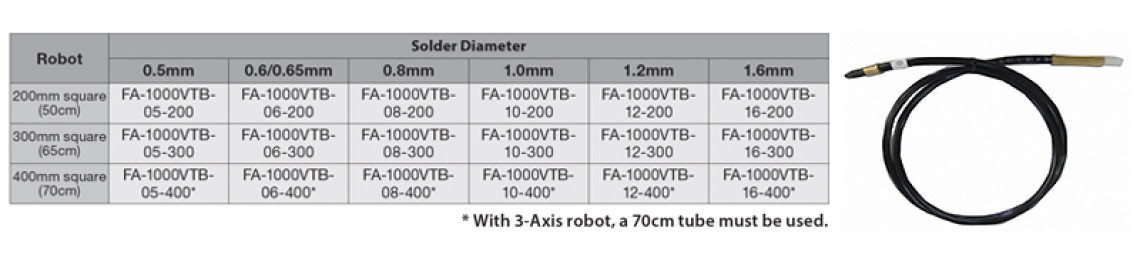

Solder-Receiving Tube FA-1000VTB

This tube passes solder from the solder reel holder to the V-groove unit. Select the most suitable tube by robot type and solder diameter.

Soldering Unit FA-1000SD

Compact and easily installed on robots and devices.

Built-in linear guide makes high-precision soldering possible. (Stroke length 10mm)

Easier to replace tips with new improved mechanism. (Tip not included)

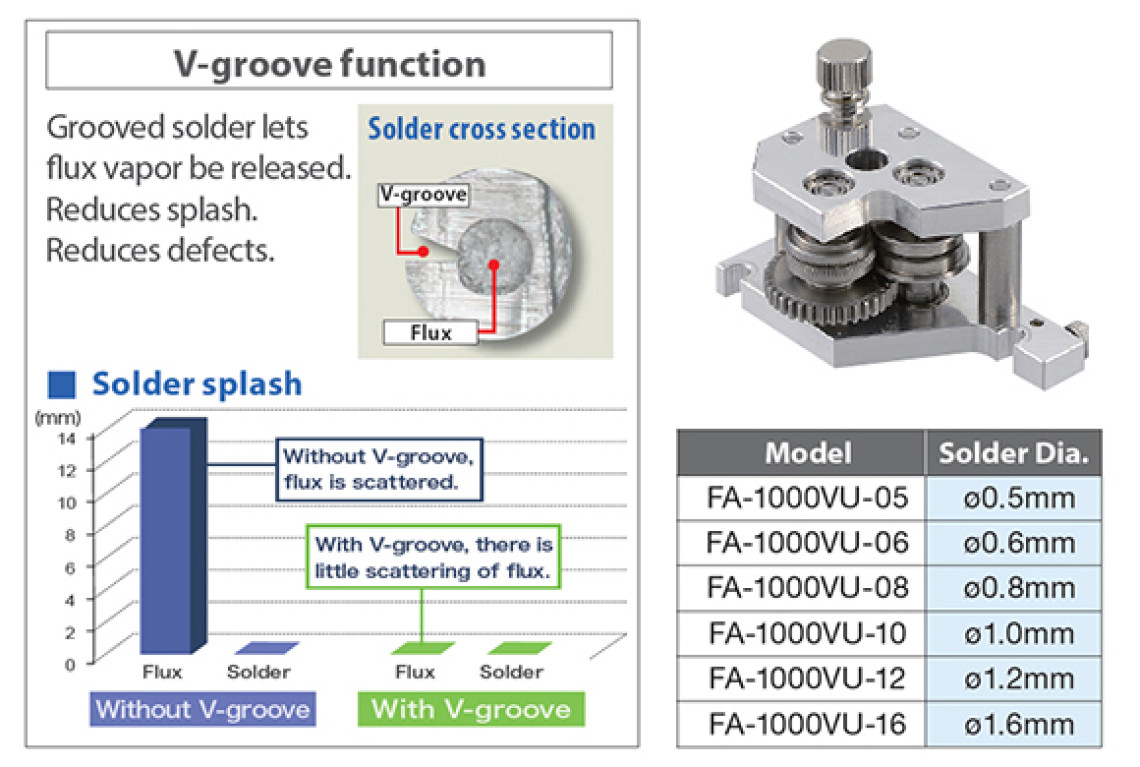

V-Groove Unit FA-1000VU

• Swappable gearbox can make V-groove.

• Vertical grooved rollers prevent solder slippage.

• Flux gas inside the solder can easily escape by V-grooving processing on the solder, and it is possible to reduce “solder and flux scattering” which causes defects.

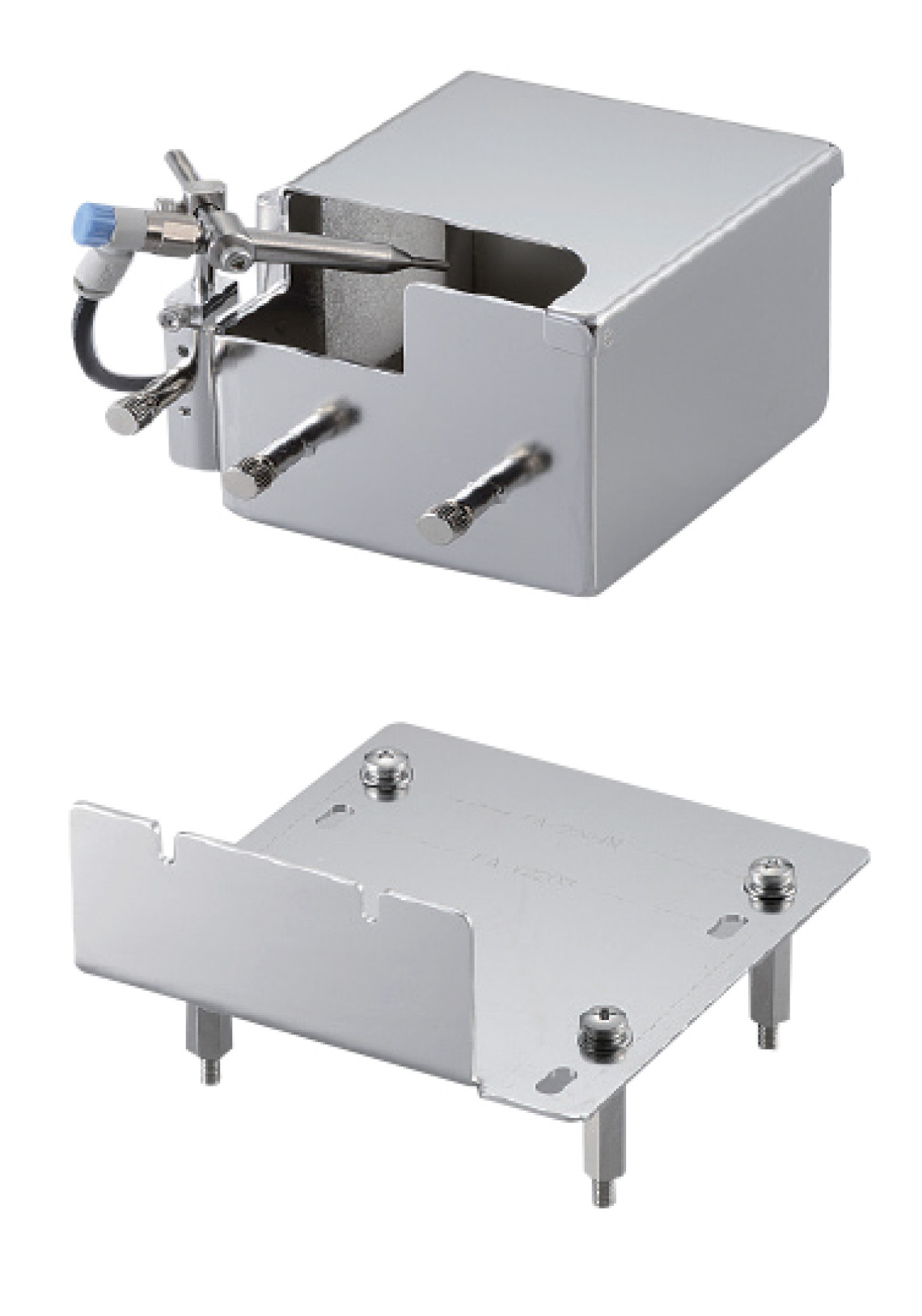

Air Blow Tip Cleaner FA-1000CL

Fan to suck up flux during air-blow cleaning is included. Easy to clean and maintain.

To attach Air Blow Tip Cleaner, you need Fixing Plate for Air Blow Tip Cleaner.

FA-1000CLP1 : For small robot (FA-3204)

FA-1000CLP2 : For big robot (FA-3304, FA-3404)

Includes a fan for sucking flux when the air blows.

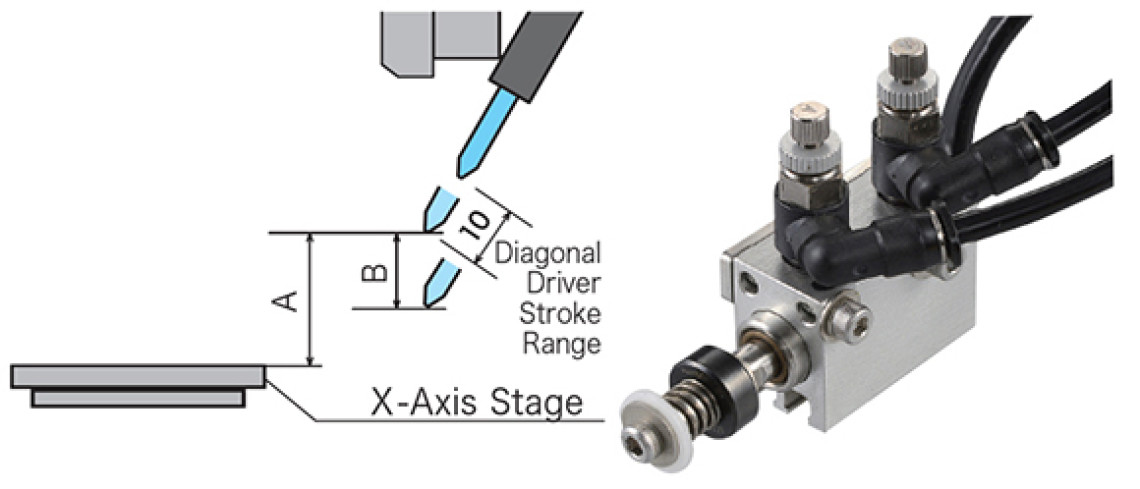

Diagonal Driver FA-1000SL

The up and down strokes of the FA-1000SD (Soldering unit) are air-driven.

Up/Down detection sensor.

Stroke length: 10mm / 4mm

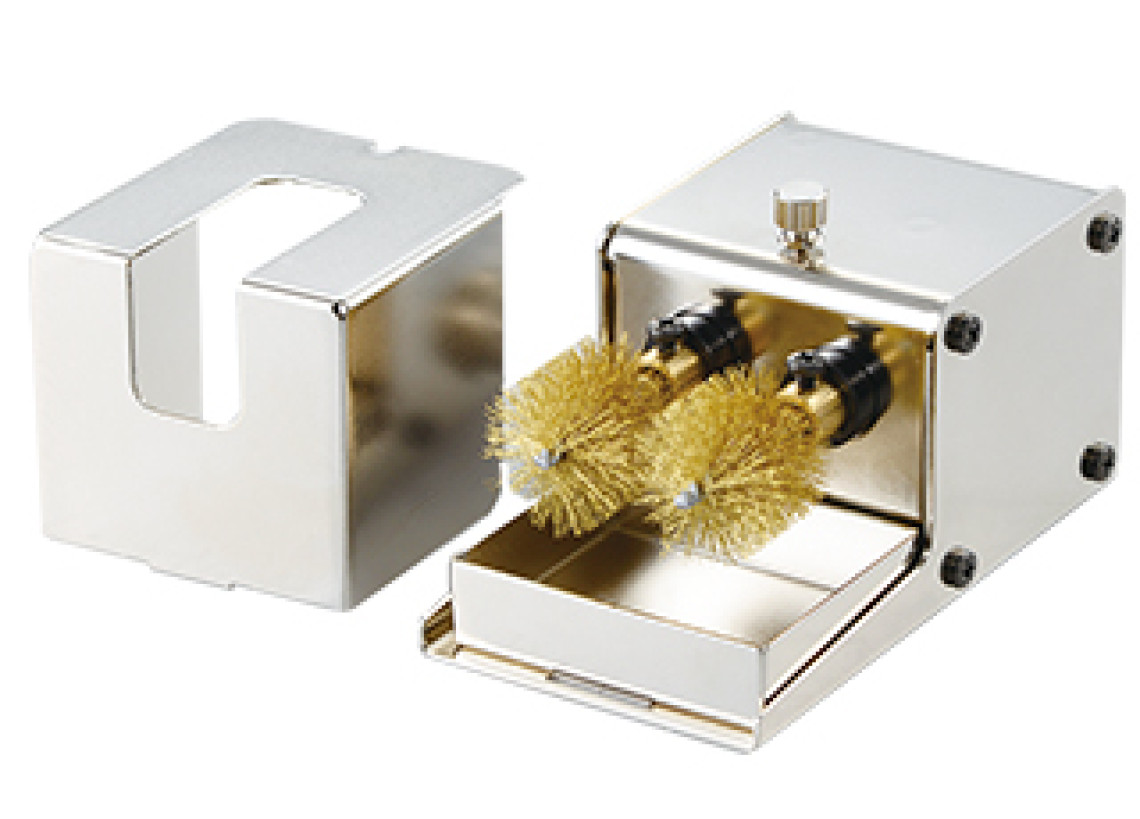

Brush Tip Cleaner FA-1000BC

To install to a robot, the Fixing Plate for the Air Blow Tip Cleaner is necessary.

Removes scorching of flux on the tip that cannot be removed by Air-blow cleaner.

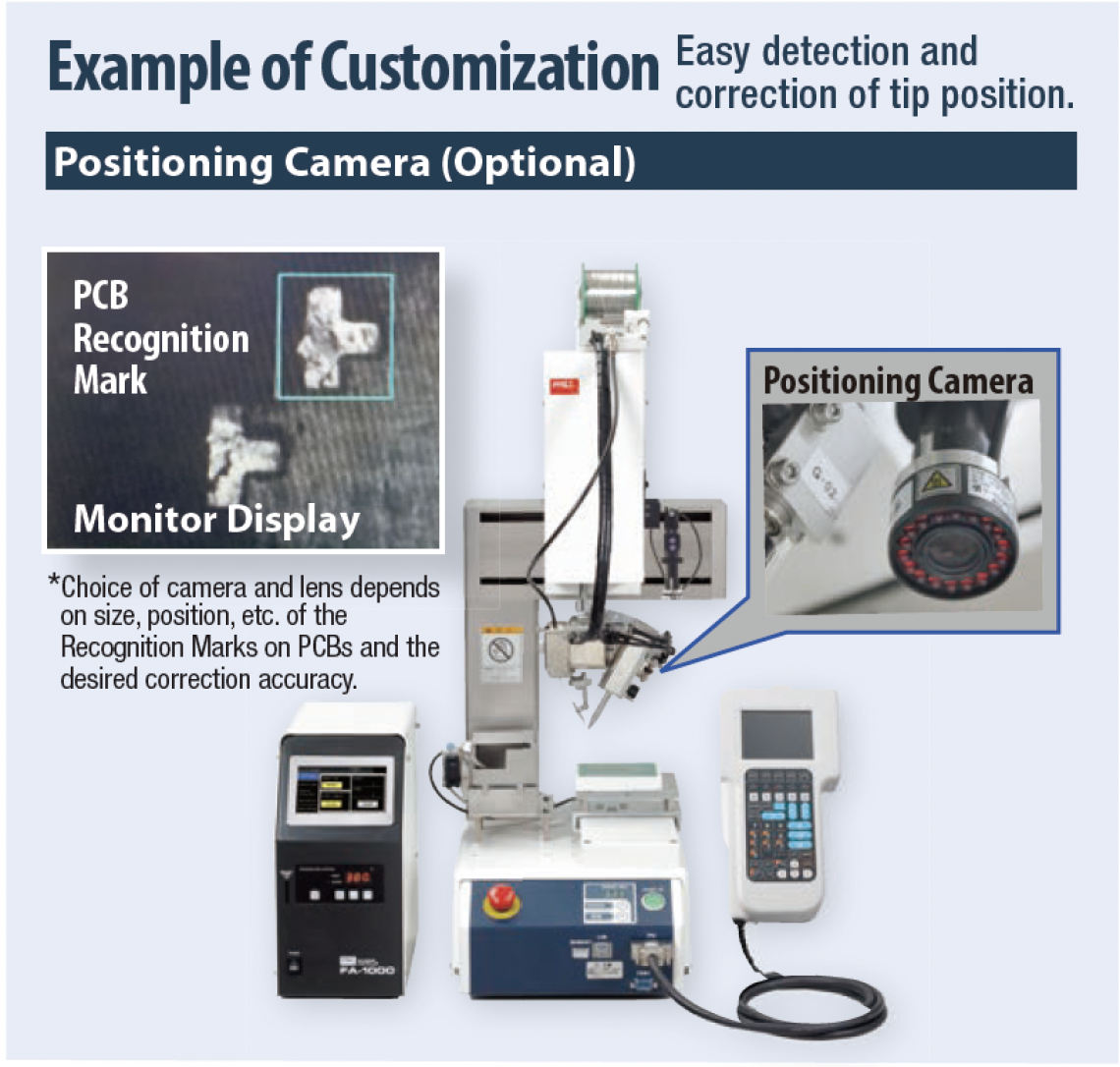

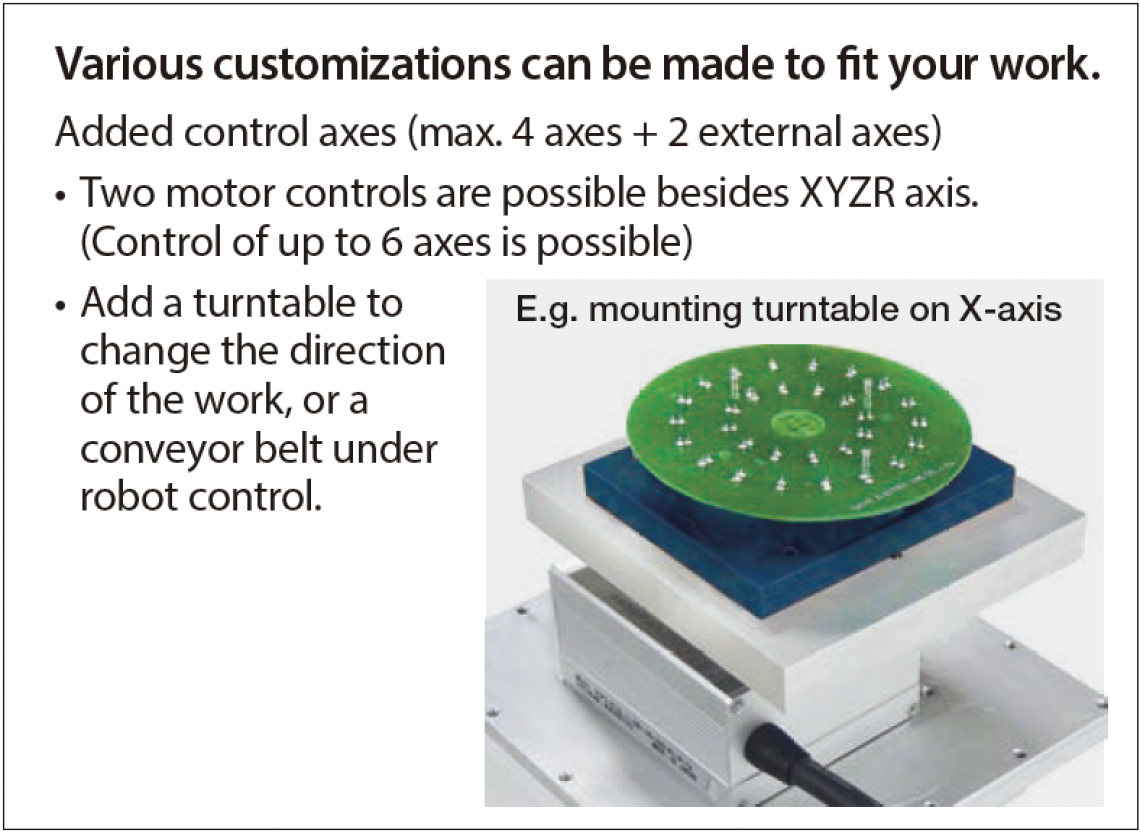

Example of Customization

Example for FA-1000 with Kawasaki Robot (Dual-Arm collaborative SCARA Robot duAro)

*Use for English subtitles.

Example for FA-1000 with DENSO COBOTTA (Collaborative Robot)

Product Specifications

|

FA-3204A |

FA-3304A |

FA-3404A |

||

|

Axis Type |

Regular 4-Axis, Optional 2-Axis (Max. 6-Axis) |

|||

|

Operating Range |

X-Axis |

200㎜ |

300㎜ |

400㎜ |

|

Y-Axis |

200㎜ |

320㎜ |

400㎜ |

|

|

Z-Axis |

50㎜ |

100㎜ |

100㎜ |

|

|

R-Axis |

±120°(Max.±360°) |

±120°(Max.±360°) |

±120°(Max.±360°) |

|

|

Shape |

Cantilever type |

Gate type |

Cantilever type |

|

|

Maximum Portable Load (Workpiece) |

7㎏ |

15㎏ |

15㎏ |

|

|

Maximum Speed |

X, Y-Axis |

700㎜/sec |

900㎜/sec |

900㎜/sec |

|

Z-Axis |

250㎜/sec |

400㎜/sec |

400㎜/sec |

|

|

R-Axis |

600°/sec |

900°/sec |

900°/sec |

|

|

Maximum Speed |

X, Y, Z Combined |

600㎜/sec |

850㎜/sec |

850㎜/sec |

|

Repeatability |

X, Y-Axis |

±0.01㎜ |

||

|

Z-Axis |

±0.01㎜ |

|||

|

R-Axis |

±0.008° |

|||

|

Work Size (Maximum Size of Jig) |

200㎜×145㎜ |

300㎜×275㎜ |

400㎜×355㎜ |

|

|

Teaching Method |

Remote teaching (JOG)/ Manual Data Input (MDI) |

|||

|

Teaching System |

Direct teaching using the optional Teaching Pendant |

|||

|

Off-line teaching with optional PC Software from a PC |

||||

|

Teaching Pendant |

Measurement Units |

mm、inch |

||

|

Languages |

Japanese, English, French, Spanish, Italian, German, Korean, Simplified Chinese, Traditional Chinese, Czech, Vietnamese. |

|||

|

Program Capacity |

999 programs |

|||

|

Data Capacity |

Up to 32,000 Points |

|||

|

External |

I/O-SYS (Standard) |

16 Inputs, 16 Outputs |

||

|

I/O-1 (Standard) |

8 Inputs, 8 Outputs (including 4 relay outputs) |

|||

|

I/O-MT/I/O-S |

I/O-MT: External Motor Control (Option) |

|||

|

I/O-S: For connecting with interlock device such as area sensor |

||||

|

COM1 (Standard) |

RC-232C for external device control, COM commands |

|||

|

COM2 (Standard) |

RC-232C for external device control (for connecting with FA-1000) |

|||

|

COM3 (Standard) |

RC-232C for external device control |

|||

|

MEMORY (Standard) |

For USB memory connection |

|||

|

LAN (Standard) |

For PC connection via the Ethernet (10BASE-T/100BASE-TX) |

|||

|

(Robot control via control commands, Connection to (optional) PC software) |

||||

|

Simple PLC Function |

Max. 100 programs, Up to 1,000 steps/1 program |

|||

|

Drive Method |

5 phase pulse motor drive |

|||

|

Control Method |

PTP (Point to Point) control, CP (Continuous Path) control |

|||

|

Interpolation |

3-dimensional linear and arc interpolation |

|||

|

Power Source |

AC100~120V (Single Phase) |

|||

|

AC220~240V (Single Phase) |

||||

|

Power Consumption |

200W |

|||

|

Operating |

Temperature |

0~40℃ |

||

|

Relative Humidity |

20-90% (Without condensation) |

|||

|

Elevation |

Up to 1,000m |

|||

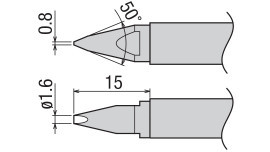

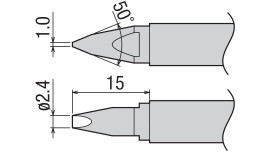

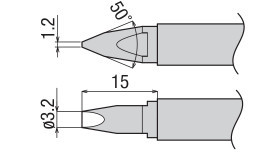

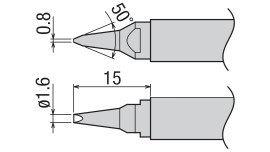

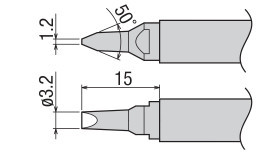

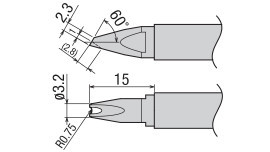

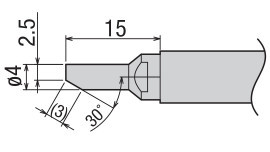

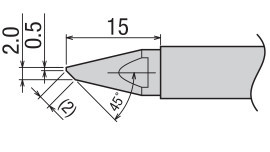

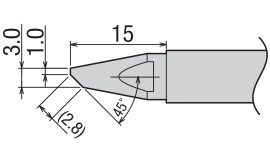

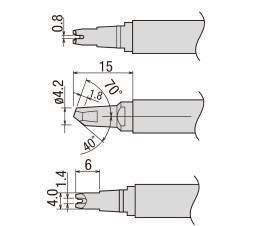

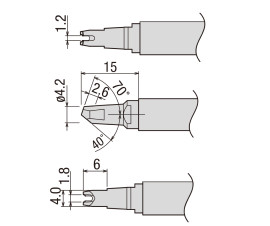

Overall View of a Tip

FA-10HRT Series

Replacement Tips

FA-10HRT-1.6D

FA-10HRT-2.4D

FA-10HRT-3.2D

FA-10HRT-1.6SD

FA-10HRT-3.2SD

FA-10HRT-3.2DV

FA-10HRT-4C

FA-10HRT-2PC

FA-10HRT-3PC

FA-10HRT-0.8W

FA-10HRT-1.2W

Search Products

Search Products

Soldering Systems

Soldering Systems Soldering Irons

Soldering Irons Automatic Solder Feeders

Automatic Solder Feeders Soldering Testers/Tip Thermometers

Soldering Testers/Tip Thermometers Solder Pots

Solder Pots Surface-Mounts/SMT Products

Surface-Mounts/SMT Products Desoldering Products

Desoldering Products Soldering Accessories

Soldering Accessories Soldering Work Materials

Soldering Work Materials Heated Tools

Heated Tools Hand Tools

Hand Tools

FA-1300/1100/1000 Series

FA-1300/1100/1000 Series

Robot Units

Robot Units

Example Installations of Other Available Robots

Example Installations of Other Available Robots